Magnesium Alloy Bull Float

A Magnesium Alloy Bull Float is a premium tool used in concrete finishing to smooth and level freshly poured concrete surfaces. View Complete Details...

Product Specification

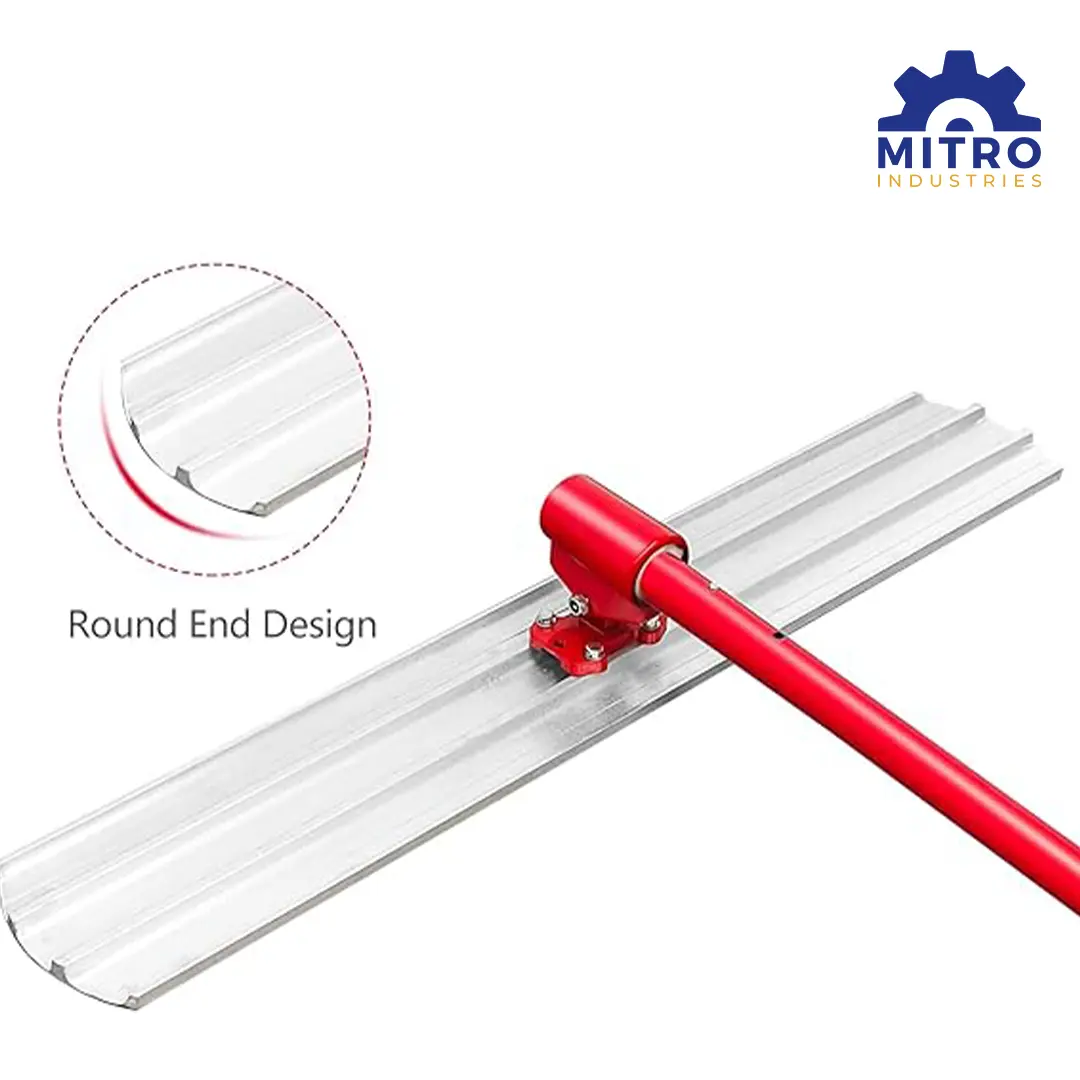

Magnesium alloy is an ideal material for bull floats due to its lightweight, durability, and resistance to rust, making it a top choice for construction professionals looking for long-lasting, efficient tools to ensure smooth, high-quality finishes on their projects.

Why Magnesium Alloy?

1. Lightweight and Easy to Handle

Magnesium alloy is much lighter than steel, allowing workers to maneuver the bull float with ease, reducing strain and fatigue, especially on larger surfaces.

The lightweight nature also makes it easier to control the tool, helping to create a more uniform finish.

2. Rust-Resistant

Unlike steel floats, magnesium alloy does not rust, even when exposed to wet concrete. This makes it a great long-term investment since it won’t deteriorate or corrode over time.

3. Durable and Strong

Magnesium alloy is highly durable and able to withstand the stresses of large-scale concrete jobs without bending, cracking, or breaking.

The material’s strength ensures the bull float maintains its shape and efficiency even after years of use.

4. Smooth and Professional Finish

Magnesium alloy bull floats provide a superior finish compared to other materials. The float helps to smooth out the surface quickly and evenly, ensuring a high-quality result for your concrete work.

It’s ideal for large flatwork projects, including driveways, patios, floors, and sidewalks.

5. Corrosion-Resistant

Because magnesium alloy is corrosion-resistant, the tool maintains its effectiveness and appearance in harsh outdoor conditions, especially when working in wet environments or with aggressive chemical additives in concrete.

How to Use Magnesium Bull Float

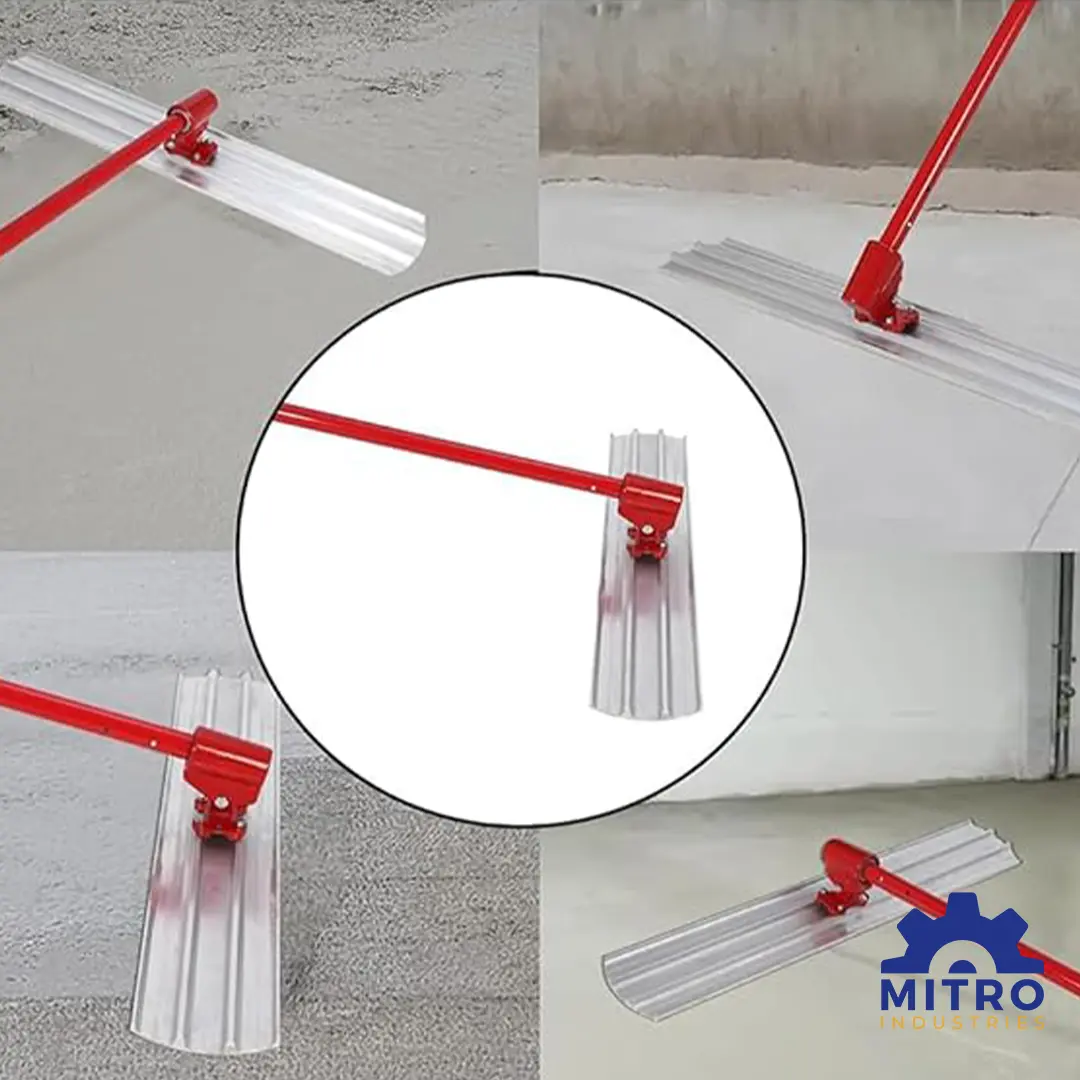

Prepare the Concrete Surface

Wait until the concrete has just begun to set but is still soft enough to float. Timing is crucial—if the surface is too wet, you may pull too much water to the surface, and if it’s too dry, you may leave unwanted marks.

Position the Bull Float

Start at one edge of the concrete slab and place the magnesium alloy bull float on the surface at an angle.

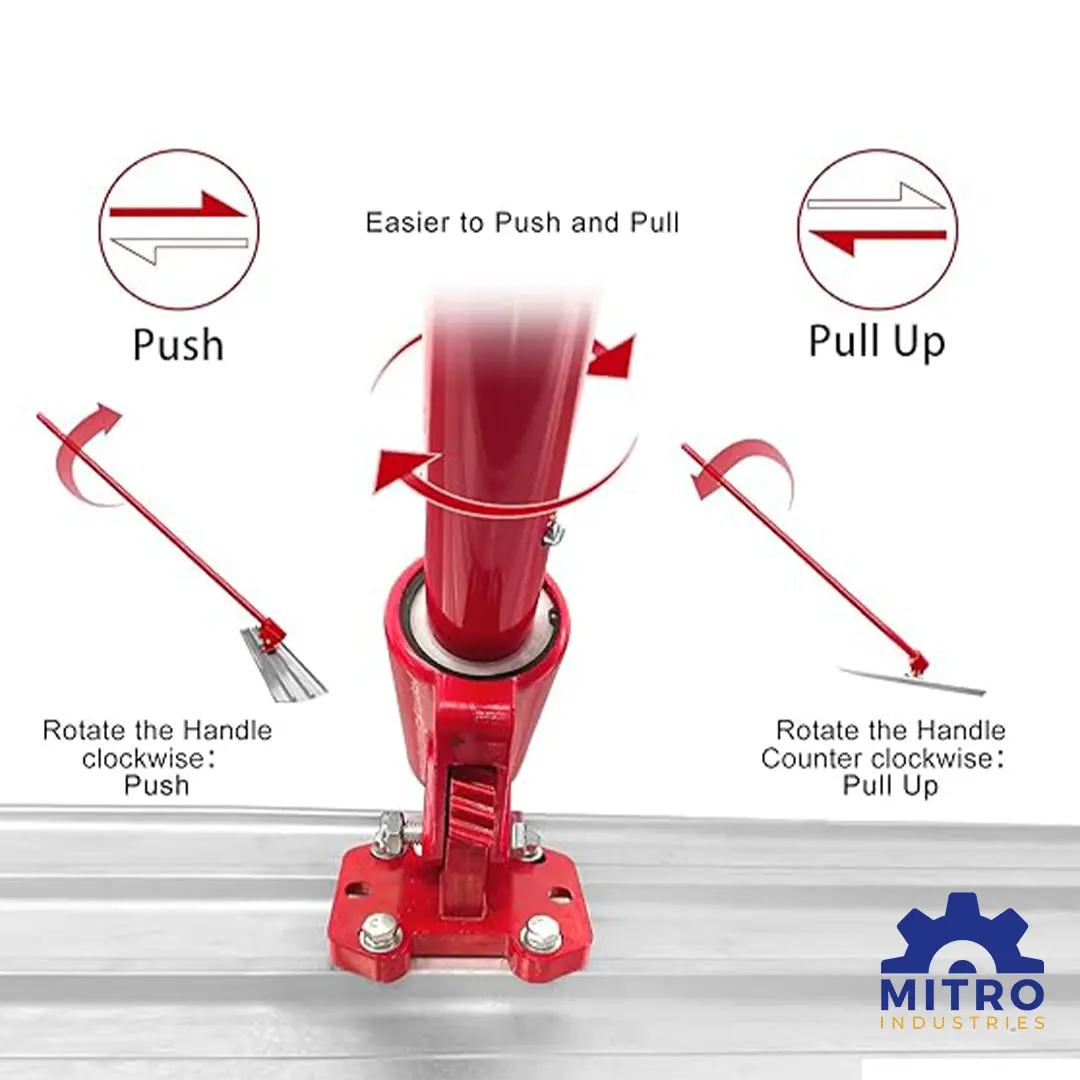

Float the Concrete

With a steady, even pressure, push the bull float in a sweeping motion across the concrete surface. The goal is to level out any inconsistencies and smooth out the surface.

Finish the Concrete

After floating, you may need to follow up with a trowel or other finishing tool to achieve the desired final texture or smoothness.

Specification

| Manufacturer | Mitro Industries |

| Material | Magnesium-Aluminium Alloy |

| Color | Red and Blue |

| Weight | 1.8 Kg |

| Number of handle | 3 |

| Floater Dimension | 48 inch * 8 inch |

| Handle Size | 70 inch * 3 |

Why Choose Mitro Industries Bull Float?

Premium Quality Construction

Enhanced Efficiency

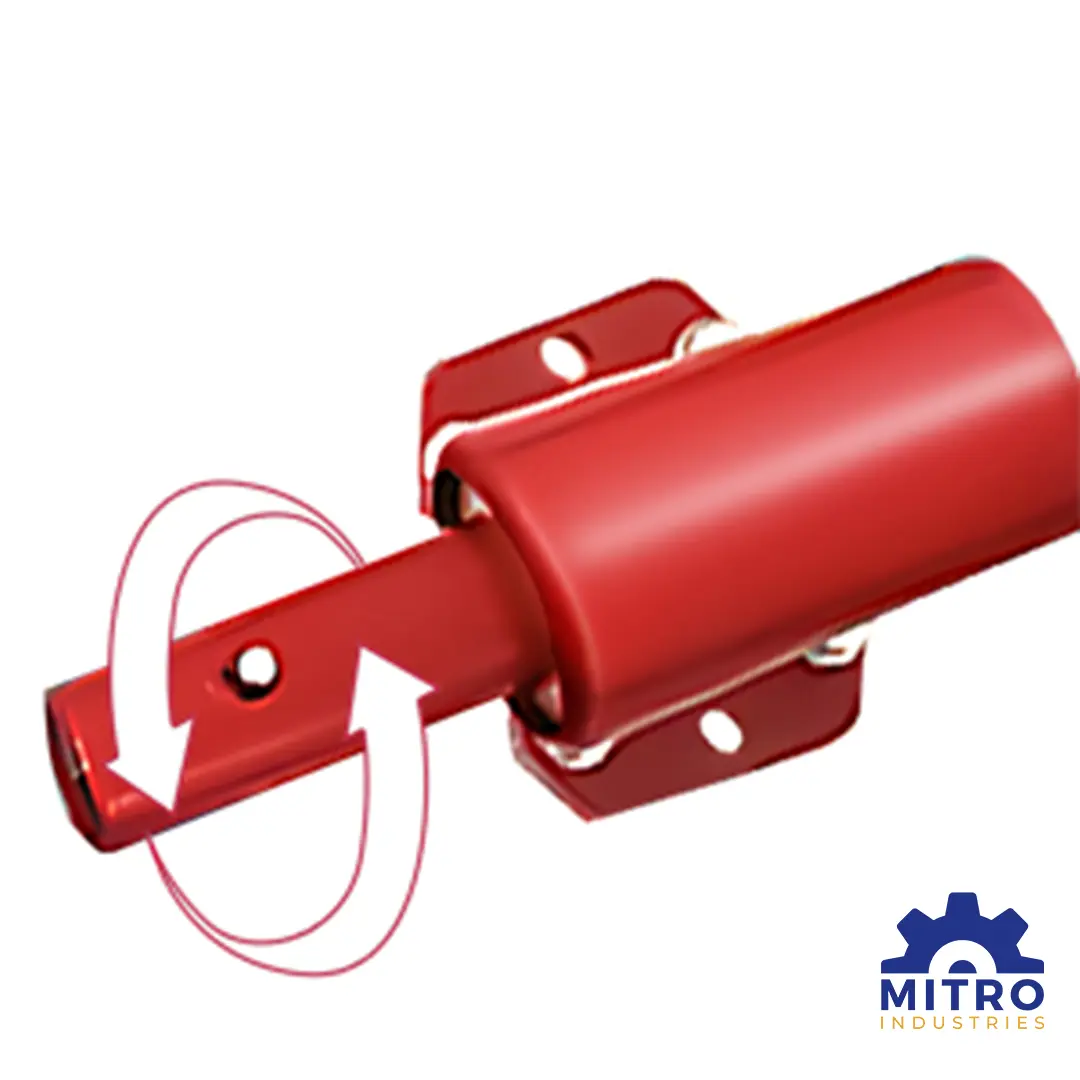

Adjustable Extended Handle

Quick and Simple Installation

Versatile Applications

Product related to Road Construction

Find a similar products you may like