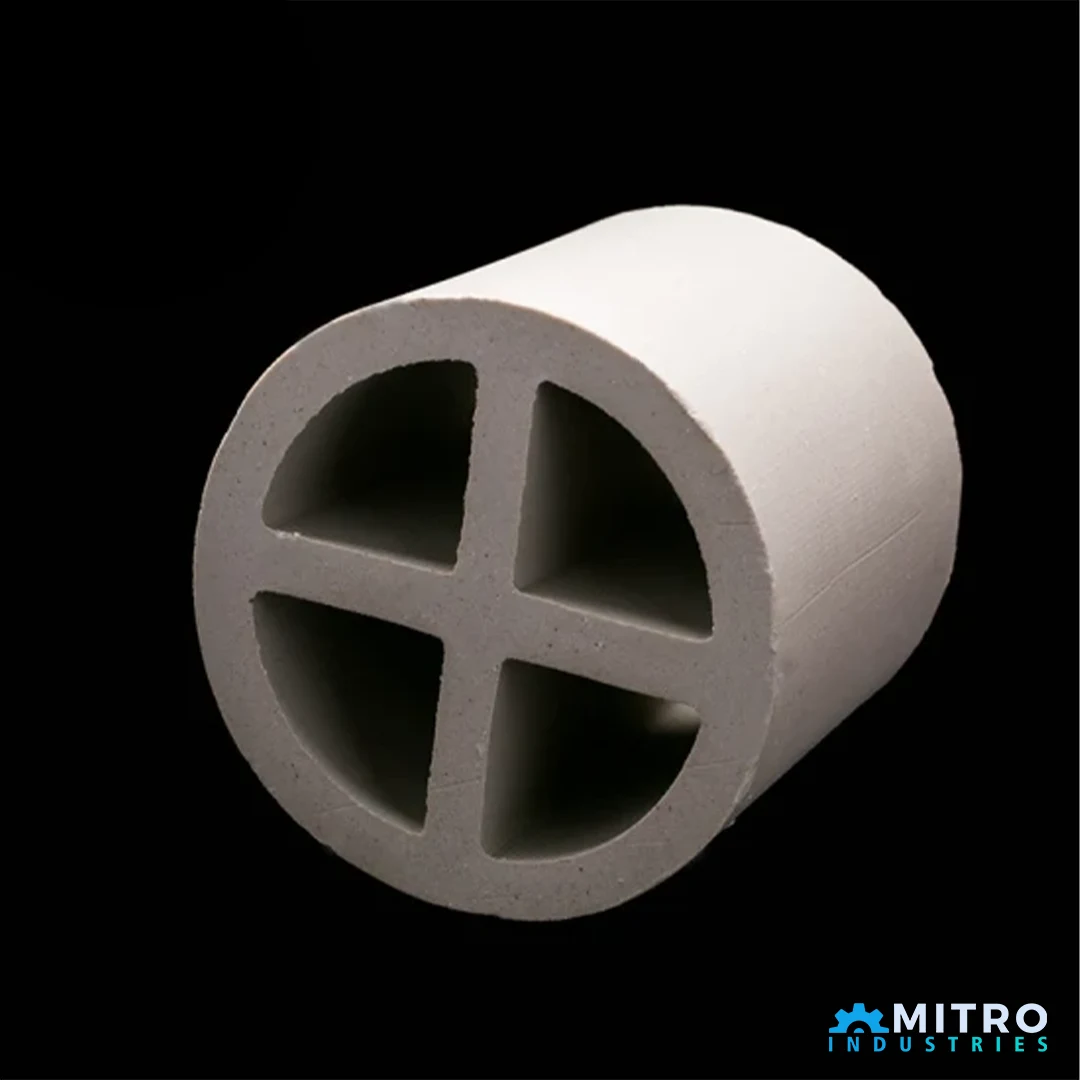

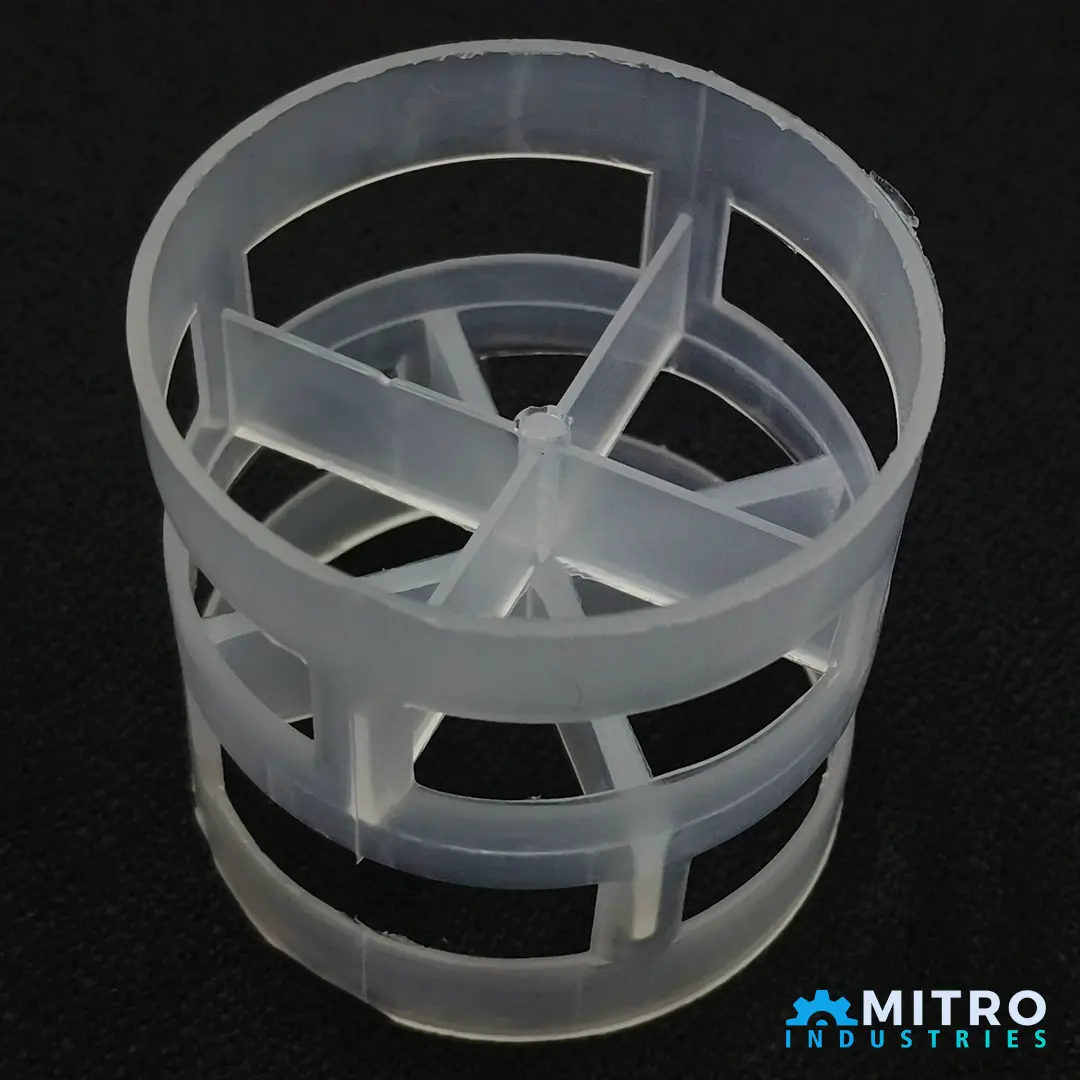

Ceramic Pall Ring

Our Ceramic Pall Rings are designed to deliver superior efficiency in tower packing applications, ensuring optimal performance in industrial processes that require effective gas-liquid contact. View Complete Details...

Products also required!

Product Specification

A Ceramic Pall Ring is a type of structured packing used in towers, columns, and reactors for gas and liquid phase separation or mass transfer processes. These rings have a unique shape, with a series of open areas that enhance the surface area for contact between gas and liquid, resulting in improved separation efficiency. Ceramic material is used for its resistance to heat, corrosion, and chemical attack, making it an ideal choice for harsh industrial environments.

Our Ceramic Pall Ring made from high-quality ceramic materials, these pall rings are ideal for use in chemical processing, petrochemical, and environmental industries where reliable and durable packing media are essential.

Features

• Superior Durability - Ceramic Pall Rings are resistant to corrosion, high temperatures, and harsh chemical environments, making them highly durable and reliable for long-term use.

• High Surface Area - The design of the pall rings increases surface area, which enhances the contact between gas and liquid, improving mass transfer efficiency.

• Efficient Gas-Liquid Contact - The unique geometry of the ceramic pall rings allows for enhanced flow dynamics, leading to better absorption, desorption, or distillation performance.

• Thermal Stability - Ceramic material can withstand high thermal shock and temperature fluctuations, making them perfect for high-temperature applications.

• Minimal Pressure Drop - Designed to provide efficient separation with minimal resistance to flow, ensuring low pressure drop across the column.

• Chemical Resistance - The ceramic composition is highly resistant to a wide range of chemicals, making it ideal for use in chemical plants and refineries.

Applications

Ceramic Pall Rings are commonly used in a variety of applications in the chemical, petrochemical, and environmental industries, including

• Absorption and Desorption Columns - To separate or absorb gases from liquids or vice versa.

• Distillation Towers - Used in separation processes where gas and liquid phases need to be efficiently mixed and separated.

• Scrubbers - For gas cleaning and pollutant removal from industrial exhaust gases.

• Ammonia and Urea Synthesis - Commonly used in the production of ammonia and urea in chemical plants.

• Solvent Recovery - In processes where solvents need to be recovered or purified.

• Petrochemical Refining - For fractionation and separation of crude oil and other petrochemical products.

• Environmental Systems - Used in wastewater treatment and air pollution control.

Ceramic Pall Ring Sizes

Why Choose Our Ceramic Pall Rings?

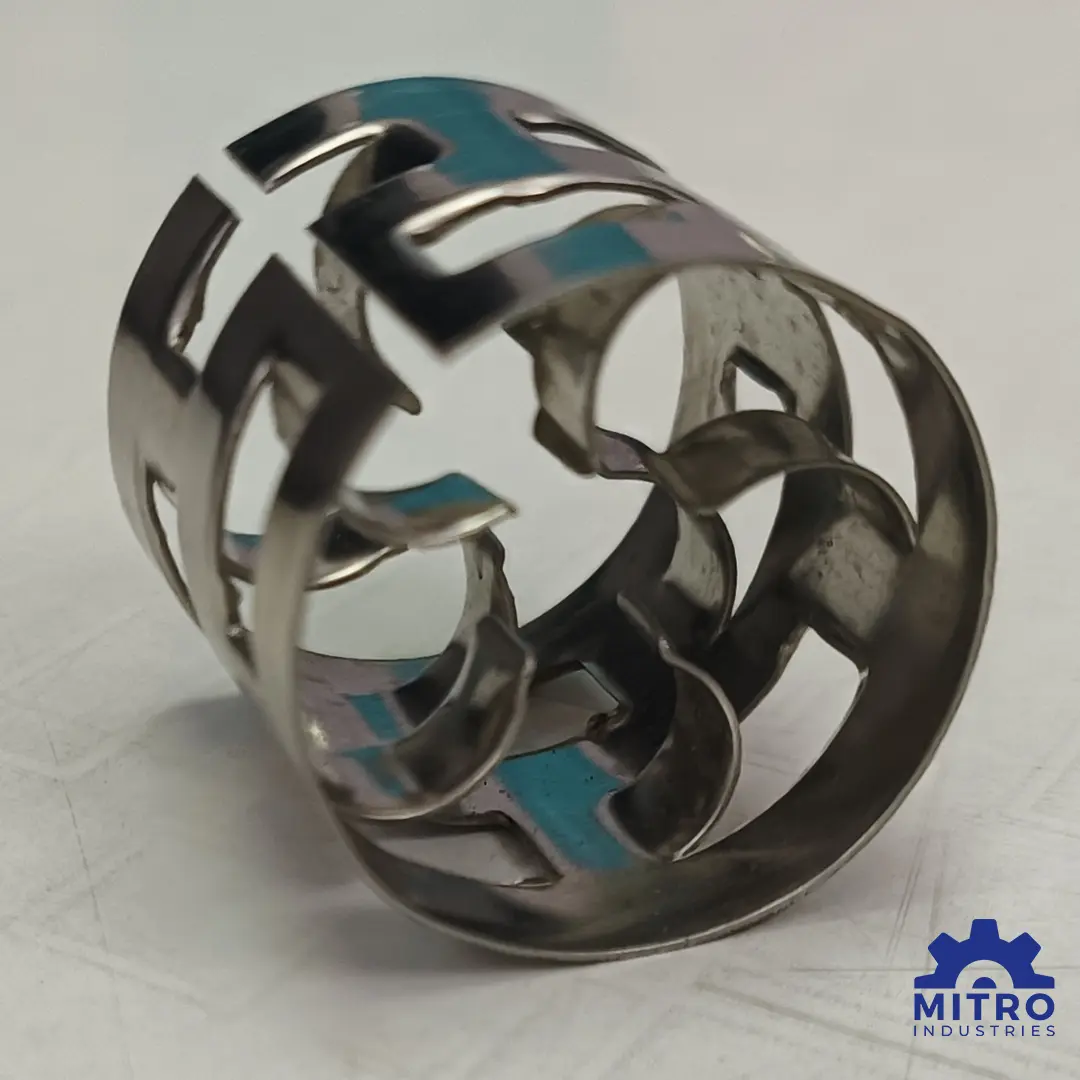

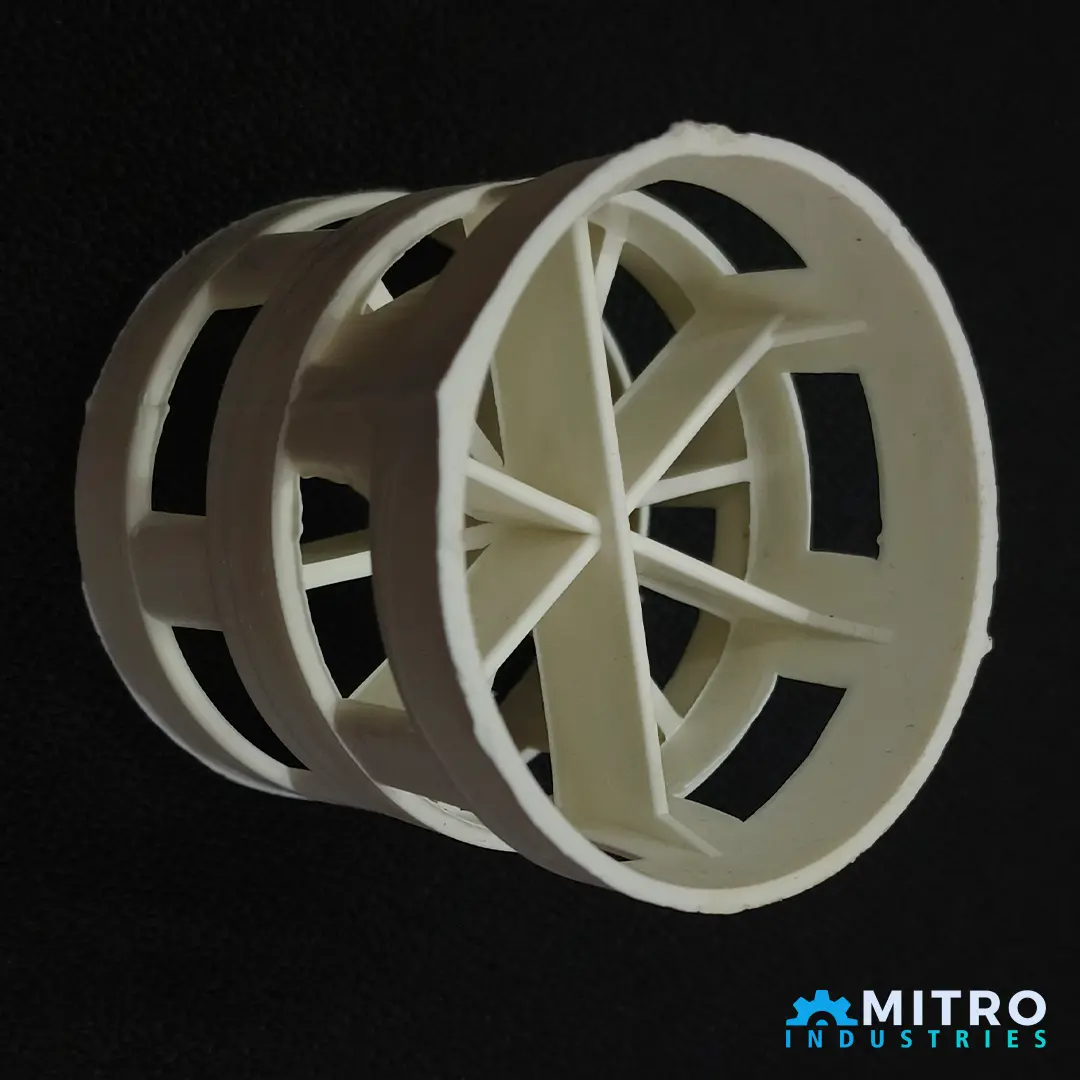

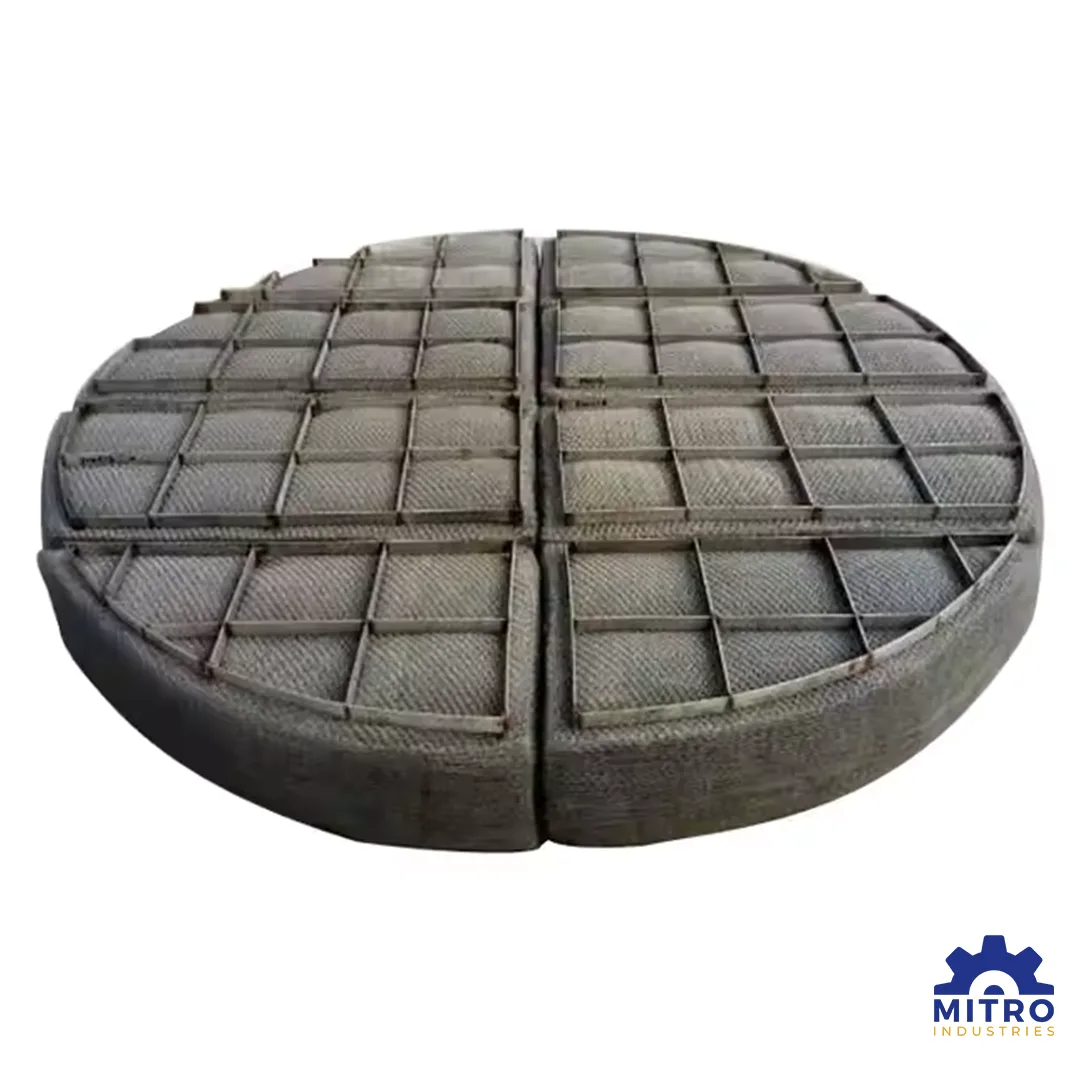

Product related to Tower Packing

Find a similar products you may like