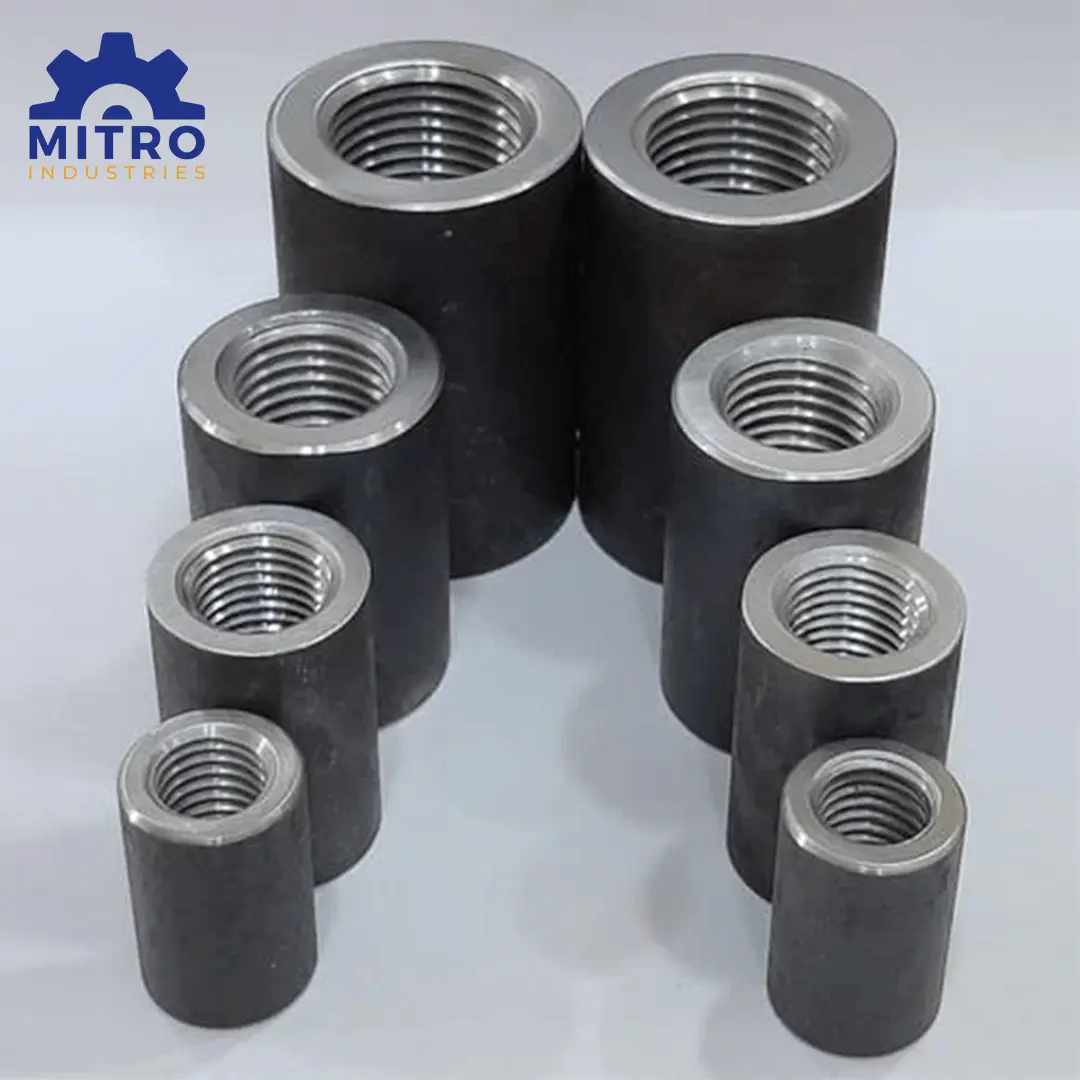

Parallel Rebar Roll Thread Coupler

Mitro Rolling parallel threaded rebar coupler, belongs to Rib peeling and rolling technology. It can connect reinforcing bar from 16 mm to 40 mm. View Complete Details...

Product Specification

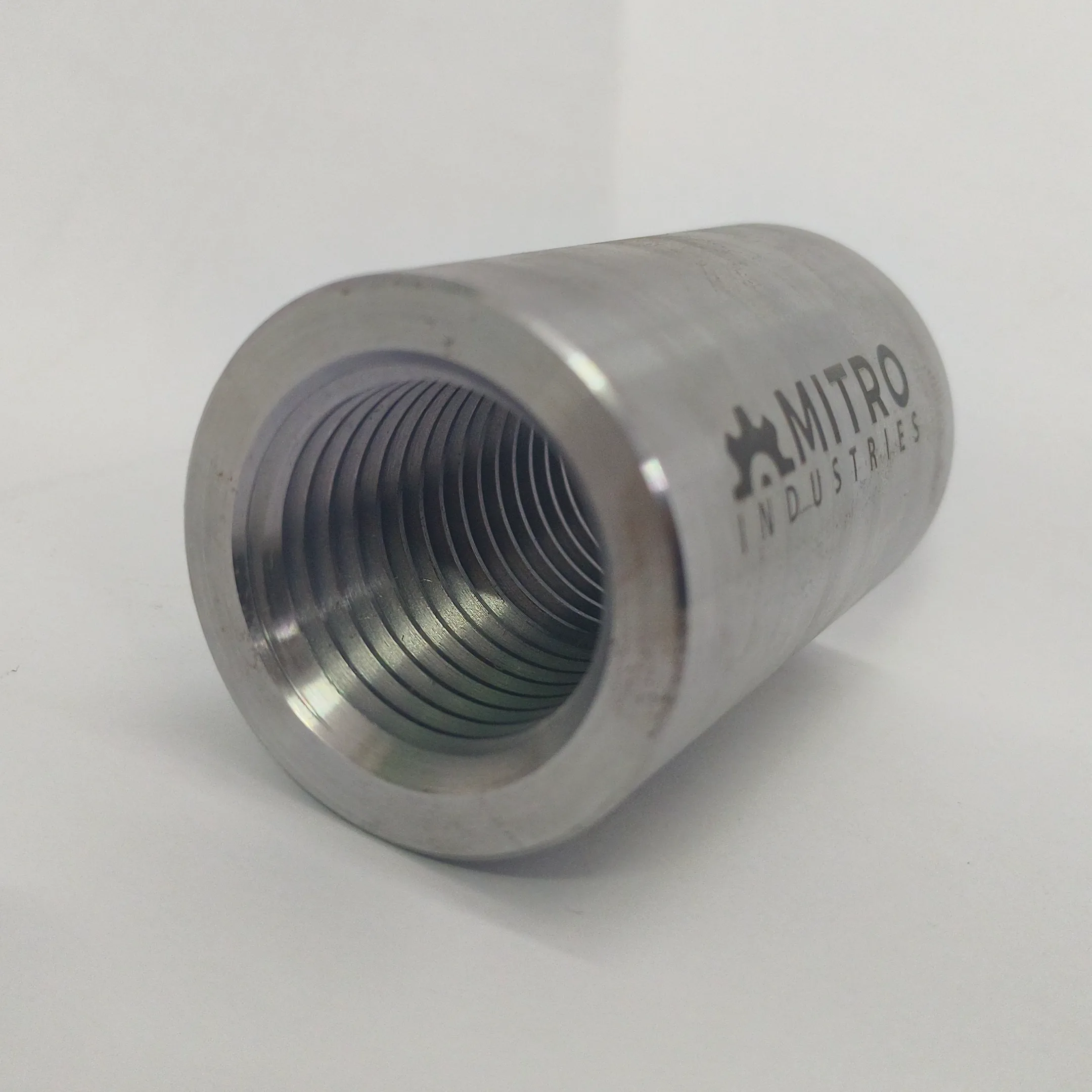

In roll thread rebar coupler, the coupler is threaded by threading machine. To fit the bar in the roll thread coupler in reinforcement, the ends of the TMT bars are threaded in the Roll Thread Machine. After that the rebar coupler installation is done to the both ends of the TMT bar like nut and bolt, for the continuous reinforcement.

Rolling Threaded rebar coupler, also known as the names rebar connector, Steel bar coupler , Reinforcing bar coupler, mechanical rebar coupler is a joint of steel bars on a parallel line which is designed for reinforcement bars and usually used in conjunction with rebar threading machine.

Rebar couplers are used in reinforced concrete structures to replace normal rebar lap joints. The couplers are also suitable for use in reinforced concrete columns and walls.

This type is rolling parallel thread rebar coupler, Belongs to Rib peeling and rolling technology.

There are 3 Kinds of inside thread

1. Inside thread is standard thread (right hand thread).

2. One side is left hand thread, another side is right hand thread.(positional rebar coupler).

3. The inside thread of two sides are different diameters(Reducer coupler).

There are different code specification in India for Rebar Coupler which is given below

Some advantages of coupler in reinforcement are

Product Features

Specification of Roll Thread Coupler

| Bar Diameter (mm) | 12 | 16 | 20 | 25 | 32 | 40 |

| External Diameter (mm) | 20 | 25 | 32 | 40 | 50 | 62 |

| Coupler Length (mm) | 32 | 40 | 50 | 60 | 80 | 90 |

| Thread Size (ID) | 10.5 | 14.5 | 18.5 | 23.5 | 30.5 | 38.5 |

| Thread Pitch | 2.0 | 2.5 | 2.5 | 3.0 | 3.0 | 3.5 |

| Weight (Kg) | 0.05 | 0.09 | 0.18 | 0.32 | 0.75 | 1.20 |

Parallel Rebar Roll Thread Preparation process

Step 1

90 degree Cutting on TMT Bar

Step 2

Threading on TMT Bar

Step 3

Fix the Coupler on TMT Bar

Product related to Rebar Coupler

Find a similar products you may like

Product Rating & Review

-

No. of review

All rating & review are verified and are from users who use the products or services.

5⭐

15

4⭐

1

3⭐

0

2⭐

0

1⭐

0

Based on 16 customer ratings

Write a Review

Read our customer reviews

D

Deepak Tyagi

"This Rebar coupler save my lakhs of money and provide 700 Mpa Strength"

A

Ashok Jangid

"Explanation of rebar coupler is good. Its clearly provide all the important information about rebar coupler."

Y

Yash mittal

"Mitro Industries rebar couplers delivered outstanding performance on our highrise project. The quality strength and easy installation exceeded expectations. Their team was supportive throughout ensuring timely delivery and technical guidance. Highly recommended for reliable rebar solutions."

P

Pramod Patel

"Quality and Strength of this coupler is good we done pull up tensile test for this and we get 650 Mpa above result"

S

Saurabh Singh

"Quality of Mitro Rebar Coupler is Good."