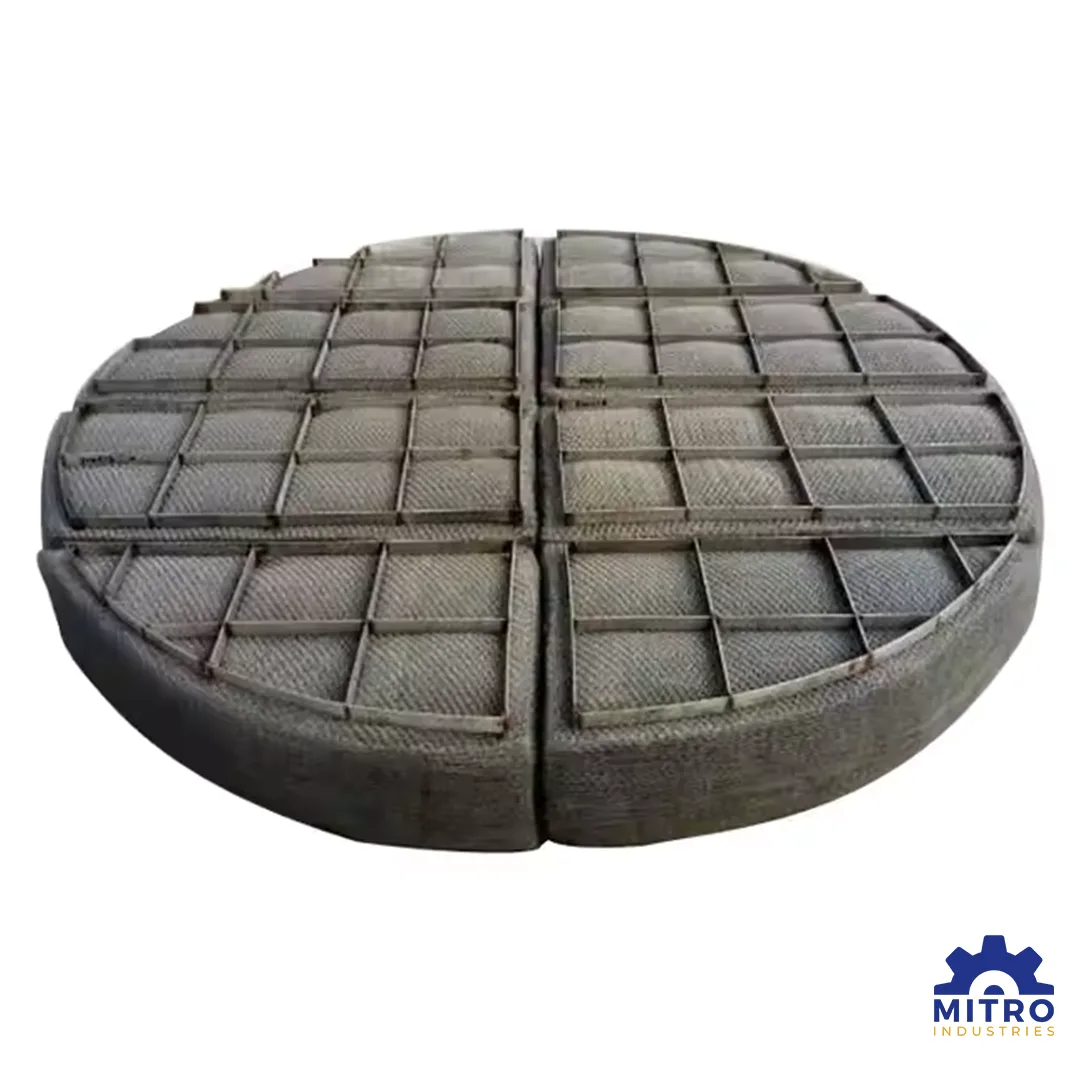

Bubble Cap Trays

Metal bubble cap trays are efficient vapor-liquid contact devices used in distillation and absorption processes. View Complete Details...

Products also required!

Product Specification

Bubble cap trays are a classic and widely used type of distillation tray, known for their effectiveness in facilitating vapor-liquid contact. These trays feature a perforated metal plate equipped with bubble caps—specialized components mounted over each perforation. Vapor rises through chimneys or slots beneath the caps and is directed outward, bubbling through the liquid layer on the tray. This bubbling action enhances mass transfer, making the trays highly effective for separation processes like distillation and absorption.

Constructed from metal, bubble cap trays are designed for high efficiency and durability. Their robust and adaptable structure makes them a reliable choice for a broad range of industrial applications, including those in the chemical, petrochemical, and refining sectors.

Key Components

• Risers - These are vertical cylindrical tubes attached to the tray deck, guiding vapor upward and channeling it into the bubble caps for effective distribution.

• Downcomers - Acting as vertical conduits, downcomers enable the controlled flow of liquid from one tray to the one below, ensuring a continuous and balanced liquid movement throughout the column.

• Weirs - Positioned along the tray edge, weirs regulate the height of the liquid on the tray and guide its flow direction, helping to maintain the right residence time for efficient mass transfer.

• Tray Plate - Serving as the tray’s main framework, this perforated metal plate contains precisely placed holes to support liquid flow and secure the installation of risers and bubble caps.

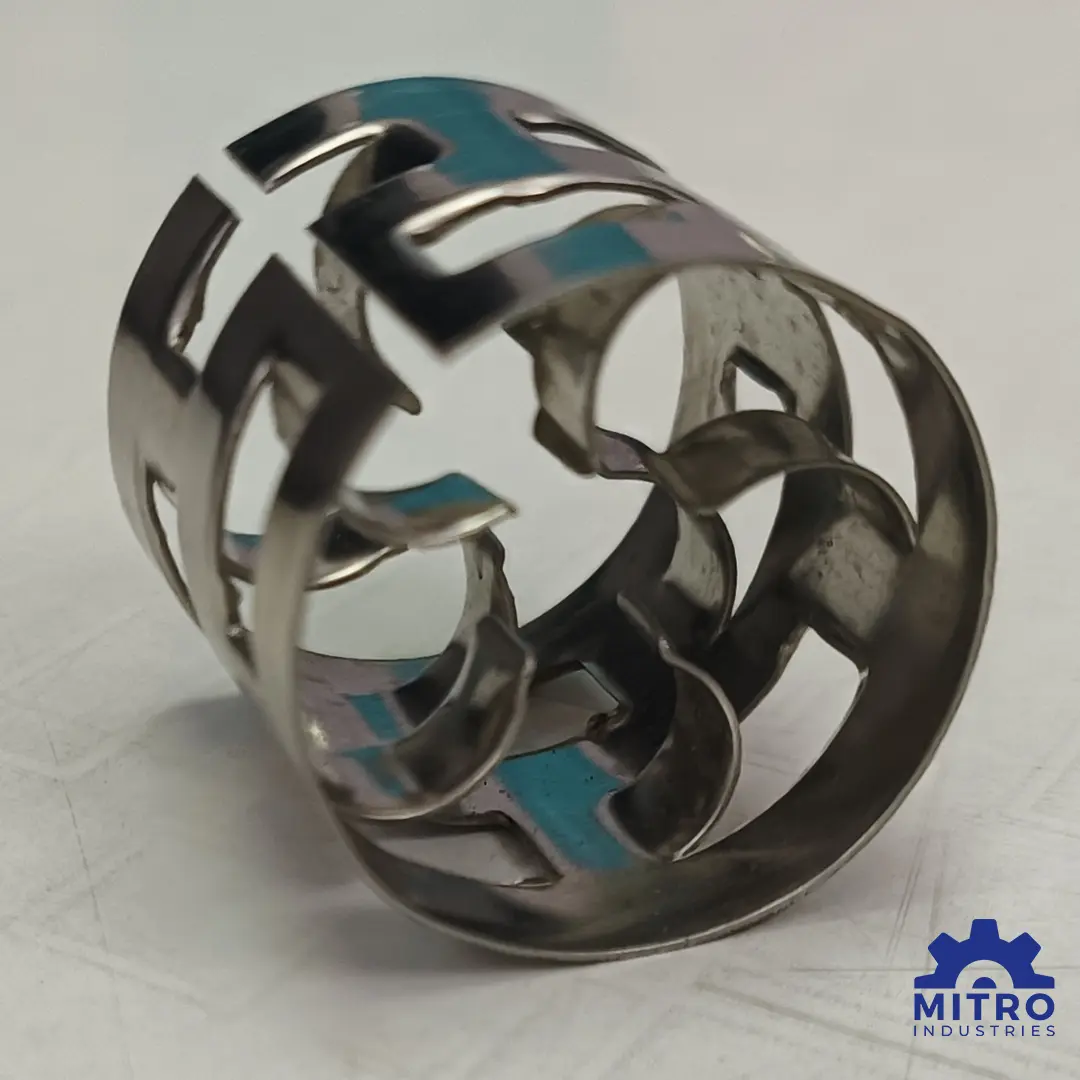

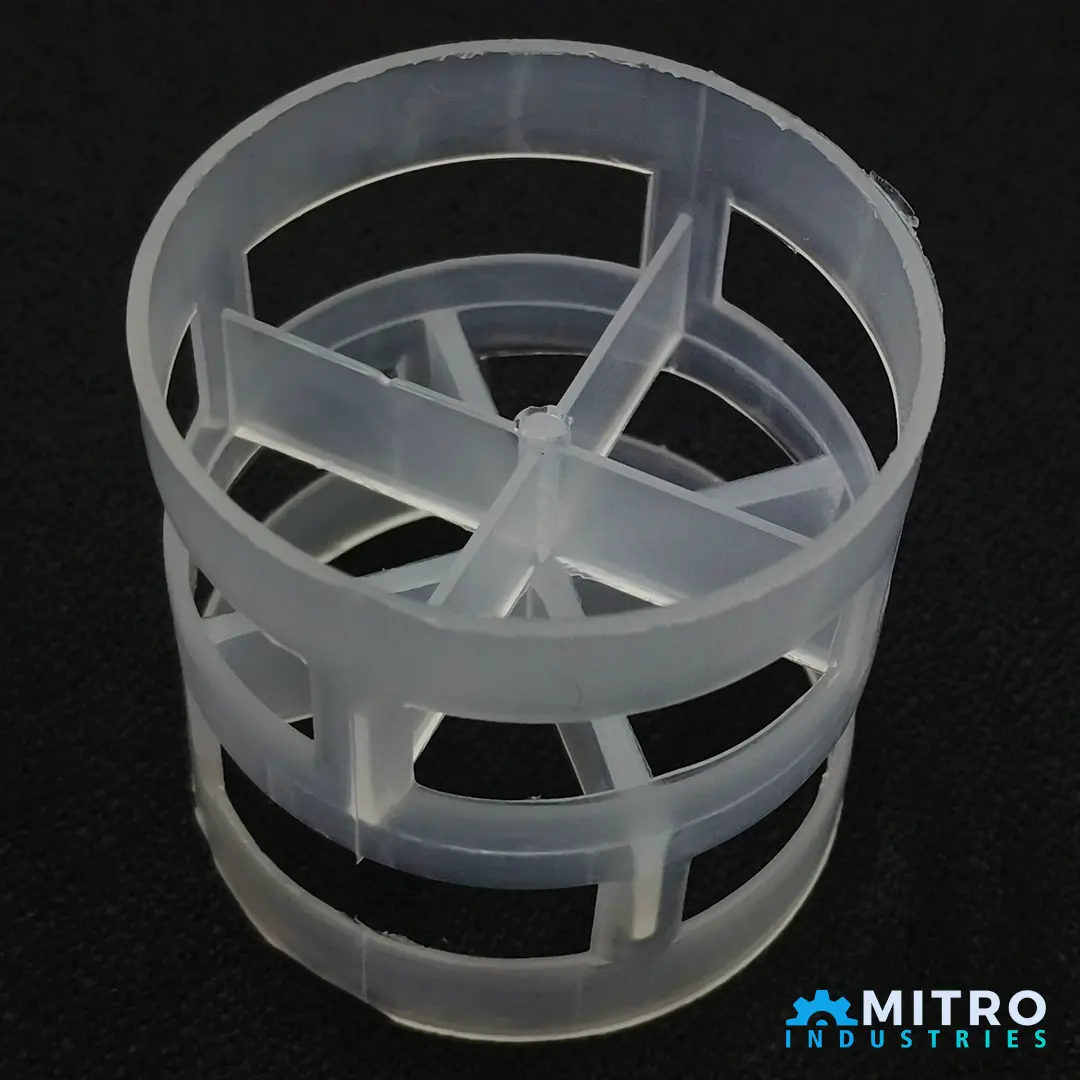

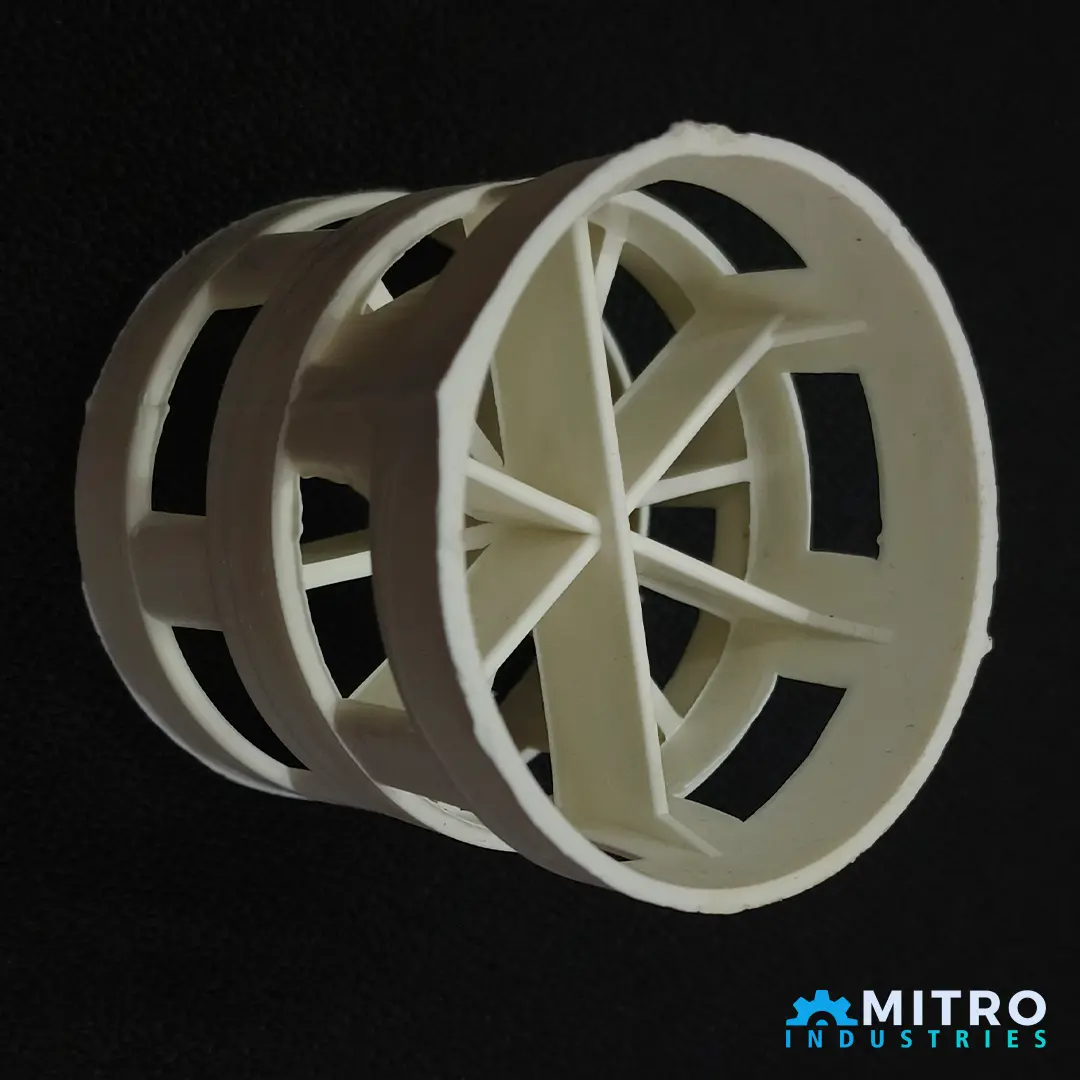

• Bubble Caps - Shaped like domes or umbrellas, these caps are fitted over risers to direct vapor through slots and into the liquid layer, dispersing it as bubbles to improve vapor-liquid interaction.

Advantages of Bubble Cap Tray

• High Mass Transfer Efficiency - The design of bubble caps promotes even vapor distribution into the liquid phase, maximizing vapor-liquid interaction and greatly improving separation and mass transfer effectiveness.

• Broad Operating Range - Delivers consistent performance across a wide range of vapor and liquid flow conditions, making it ideal for processes with variable operating parameters.

• High Throughput Capacity - Engineered to manage large volumes of vapor and liquid, making it well-suited for demanding industrial-scale applications.

• Stable and Reliable Operation - Constructed with durability in mind, the trays offer excellent resistance to fouling and mechanical wear, ensuring long-term, low-maintenance performance even in tough environments.

• Sealed to Prevent Leaks - A tight sealing design minimizes liquid leakage and vapor bypass, maintaining operational efficiency and enhancing product purity.

• Clog-Resistant Design - Bubble caps are specifically shaped to prevent blockages from solids or viscous fluids, making them suitable for handling challenging feed mixtures.

Cap Sizes & Material

Sizes : 3in, 4in, 5in & Custom

Material : SS, Copper, Carbon Steel, Alloys & Custom

Applications of Bubble Cap Tray

• Petrochemical Industry

In the petrochemical industry, bubble cap trays are widely applied in processes like olefin separation and aromatic refining. Their durable construction allows them to operate reliably under high-temperature and high-pressure conditions, ensuring consistent vapor-liquid interaction. This enhances mass transfer efficiency and contributes to higher product purity in applications such as ethylene production and benzene purification.

• Refining

In refining processes, bubble cap trays are essential components in both atmospheric and vacuum distillation columns. They enable efficient separation of crude oil fractions by ensuring consistent vapor distribution and adequate liquid retention, which supports effective phase interaction and separation.

• Pharmaceuticals

In the pharmaceutical industry, bubble cap trays are commonly used for solvent recovery and product purification. Their ability to provide accurate and consistent vapor-liquid contact ensures high product purity and prevents cross-contamination. This makes them ideal for controlled distillation environments where maintaining strict quality standards is essential.