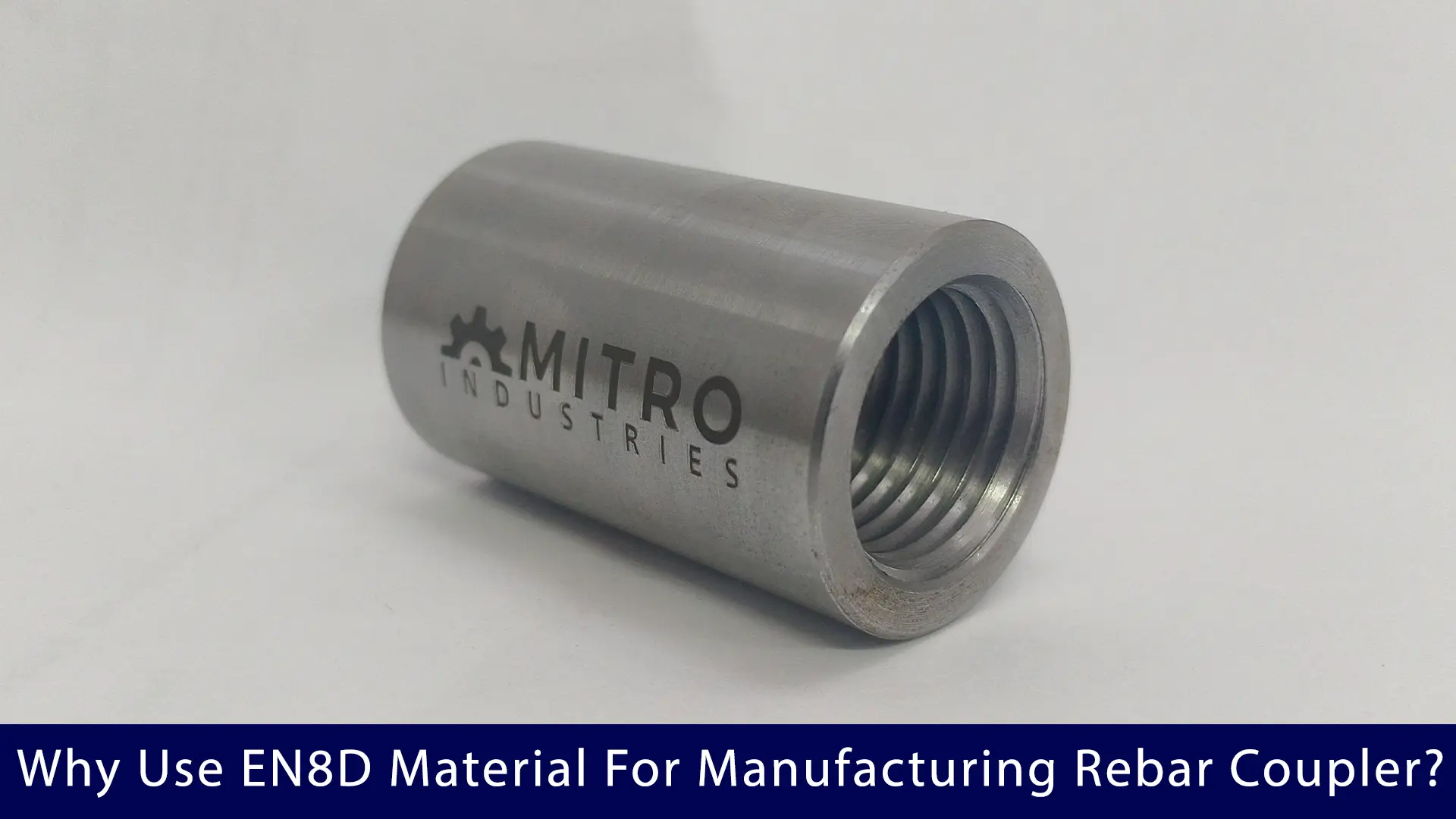

Why Use EN8D Material For Manufacturing Rebar Coupler?

16 Jun 2025

Construction

1908

"EN8D steel is an ideal material for manufacturing rebar couplers, ensuring that they meet the mechanical and structural demands of construction projects."

EN8D material is commonly used for the manufacturing of rebar couplers due to its specific mechanical properties that make it suitable for high-strength, durable applications such as in construction. Here’s why EN8D steel is favored for rebar coupler manufacturing

1. Strength and Durability

EN8D is a medium-carbon steel with excellent tensile strength and wear resistance, making it suitable for heavy-duty applications. Rebar couplers need to withstand significant tensile and shear forces in construction structures, and EN8D provides the strength required to ensure that the couplers perform well under load without failing or deforming.

2. Good Hardenability

EN8D can be hardened effectively, which enhances its wear resistance and structural integrity. Rebar couplers, being used in critical joints for reinforcing steel bars (rebars), need to have high hardness to resist wear and tear over time, especially in environments subject to high stress.

3. Machinability

EN8D steel offers good machinability, which is important for producing the precision threads that rebar couplers require. The material allows for easy processing to the desired dimensions and thread patterns, ensuring a secure and tight fit when the coupler is used to join rebars.

4. Corrosion Resistance

While EN8D steel is not as corrosion-resistant as stainless steel, it still provides good resistance to rust and corrosion compared to low-carbon steels. This makes it a practical choice for rebar couplers, as they are exposed to humid or wet environments in construction settings where some level of corrosion protection is necessary.

5. Cost-Effectiveness

EN8D is relatively cost-effective compared to higher alloy steels or stainless steels, which helps keep the manufacturing cost of rebar couplers reasonable while still offering excellent performance. This is important in large-scale construction projects where cost efficiency is critical.

6. Versatility

EN8D can be used for manufacturing a wide range of mechanical components, and its properties are well-suited for creating the high-strength, reliable rebar couplers required for various construction applications.

Due to its balance of strength, machinability, and durability, EN8D steel is an ideal material for manufacturing rebar couplers, ensuring that they meet the mechanical and structural demands of construction projects. It provides a cost-effective solution while still maintaining high performance in terms of tensile strength and wear resistance.

Popular Posts

-

Why use Demister Pad in tower packing?

1586 Views -

Why Armour Joints use for Flooring?

1725 Views