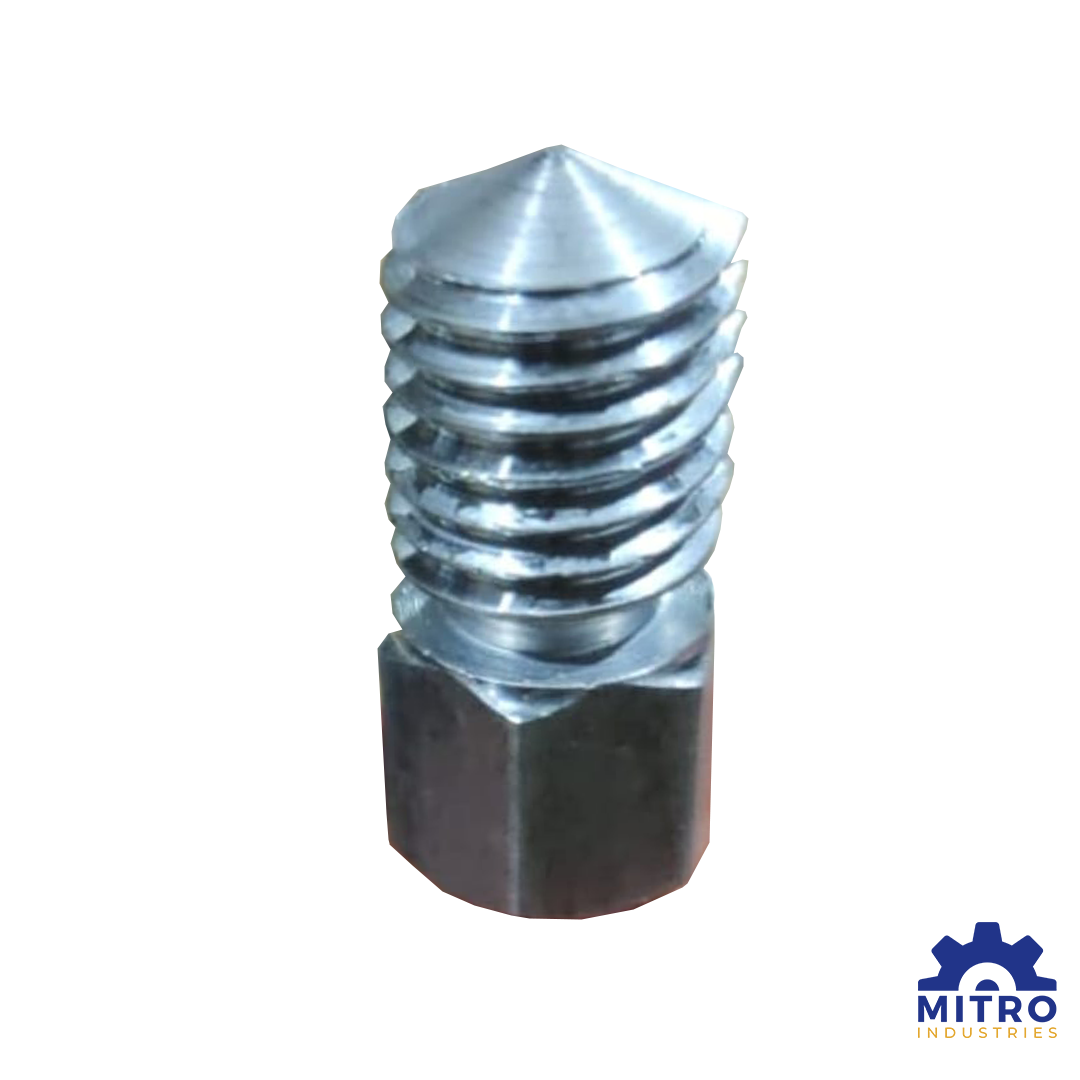

High speed tensile Rebar MBT Coupler

We Manufacture MBT Coupler to our CNC Machine and we used EN8D Material for our MBT Coupler. EN8D Material Provide Good Strength in your Construction Projects. View Complete Details...

Product Specification

The MBT coupler range provides a cost-effective method of joining reinforcing bars, particularly when the fixed bar is already in place and there is insufficient space for a hydraulic swaging press. They are easy to install and achieve failure loads higher than 108% of the characteristic yield strength of grade 500 reinforcing bar. Neither bar end preparation to form threads, nor bar rotation is required. MBT couplers can also be used to join imperial or metric plain round or deformed reinforcing bars, making it ideal for alteration or refurbishment projects.

The bar ends are supported within the coupler by a patented reversed teeth inner wall, and as the lockshear bolts are tightened, the conical ends embed themselves into the bar. As this happens the reversed teeth bite into the bar. The lockshear bolts of couplers up to and including the 20mm bar can be tightened using a wrench. For larger couplers, a nut runner is recommended. In all cases, heavy-duty sockets should be used.

When the pre-determined tightening torque for the bolts is reached, the heads shear off leaving the top of the installed bolt slightly proud of the coupler. This provides an instant visual check of correct installation.

Product related to Rebar Coupler

Find a similar products you may like