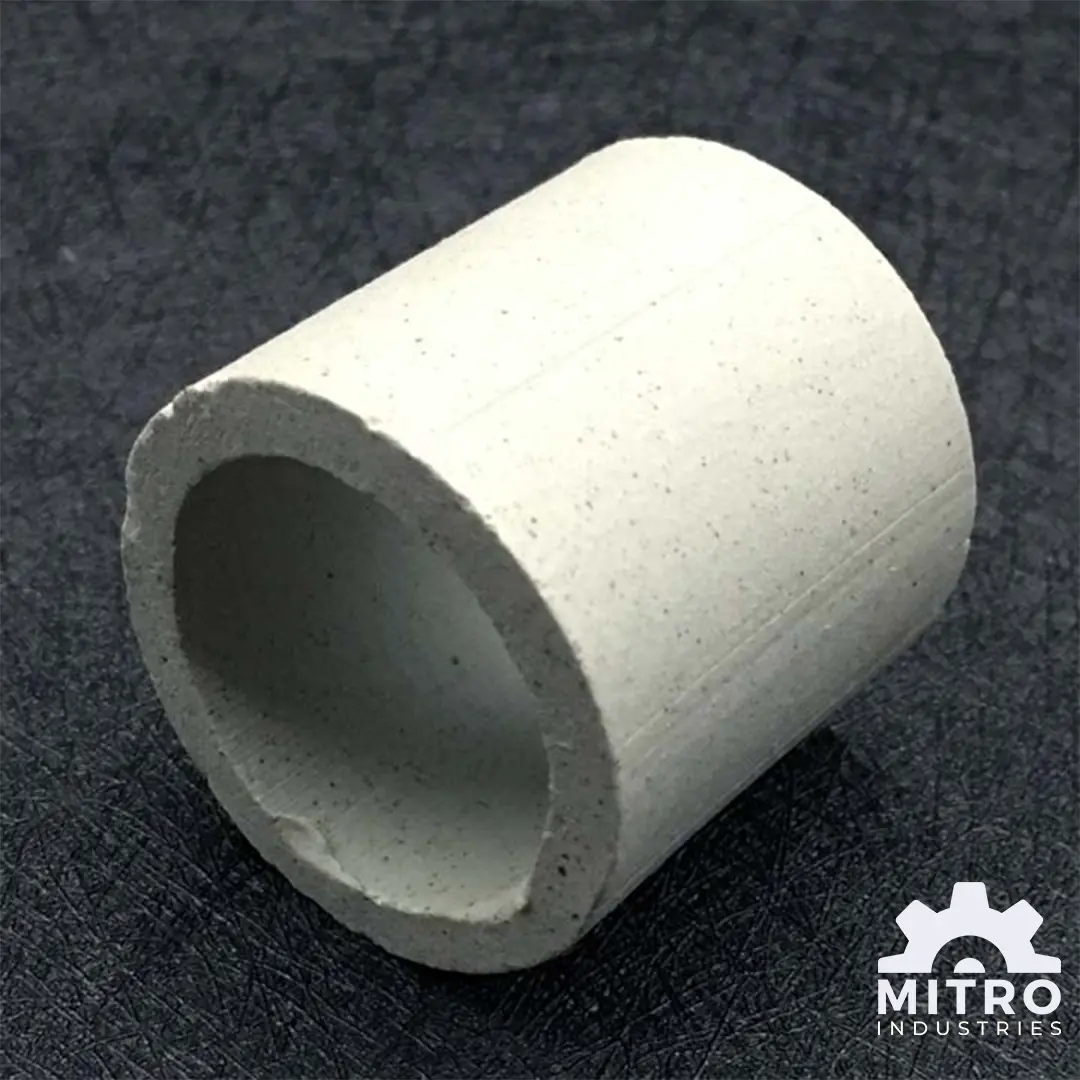

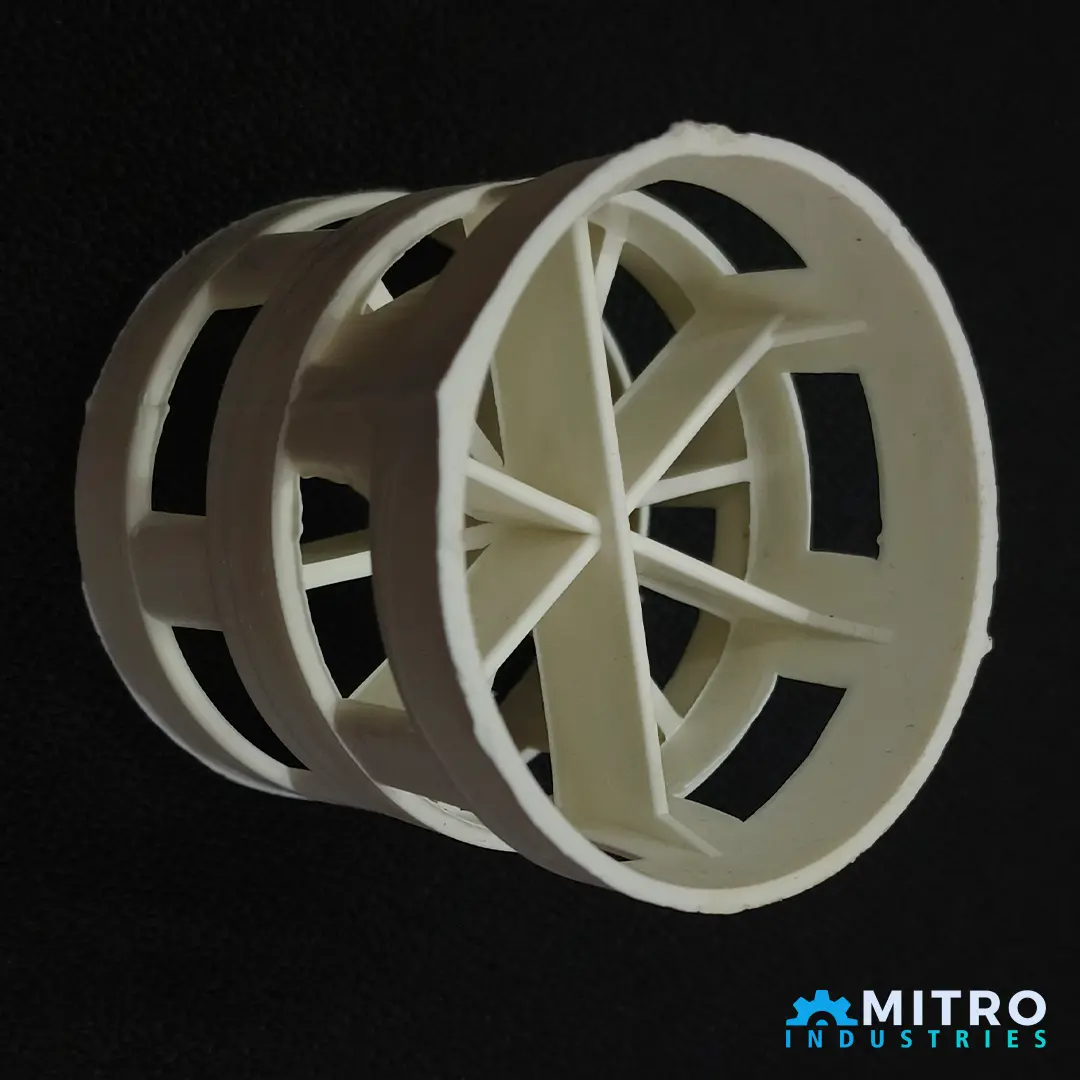

Ceramic Raschig Rings

We offer the best Ceramic Raschig Rings on the market. Small sized pickings held together as a column bed is supported by cross partition rings that are fixed at the bottom of the column. View Complete Details...

Products also required!

Product Specification

The primary use of raschig rings is to ensure the production of stronger and purer ethanol. Raschig Rings are highly applicable in the production of alcoholic beverages. Stacking these rings in the distilling columns assists ethanol vapour in moving to the condensing units while hindering vapours attained from other harmful substances from reaching these units

Raschig rings are stacked in distilling columns while producing alcoholic beverages to assist in channelling ethanol vapour directly to the condensing units. These rings are also responsible for hindering vapours emanating from other harmful substances from proceeding to the condensing chambers.

We offer the best Ceramic Raschig Rings on the market. Small sized pickings held together as a column bed is supported by cross partition rings that are fixed at the bottom of the column.

To attain long lasting performance while offering the best services, the products are manufactured in compliance with all the industrial manufacturing standards.

These super quality rings are extensively applied in various random packaging activities, therefore, providing to be more useful.

Features

Fine finishing creating a spectacular view.

Supper efficient

Superior in quality standards

Sturdier in operations

Longer shelf life

Efficient in performance

Highly flexible

Dimensional accuracy

Quality assurance

Compact design

Long lasting

Non-corrosive

Application

Raschig rings are highly applicable in distillation columns in the production of beverages.

Used in plants handling liquids and gases for ensuring that chemical reactions, gas absorptions, and or stripping.

Borosilicate Glass Raschig rings are used in handling nuclear materials. Tanks and vessels containing fissile material solutions are laced with this type of rings to enable smooth and less risky operations. For example, Uranyl Nitrate enriched solutions need borosilicate glass raschig rings to prevent accidents.

Specification

| Spec (mm) | D*H*T (mm) | Number per m3 (pcs) | Surface area (m2/m3) | Void Volume (%) | Drying Packing Factor (m-1) |

| 15 | 15×15X0.4 | 250000 | 330 | 70 | 960 |

| 25 | 25X25X0.5 | 49000 | 190 | 78 | 400 |

| 50*50 | 50×50X0.8 | 6000 | 93 | 81 | 305 |

| 100 | 100X100X0.7 | 1000 | 70 | 70 | 170 |

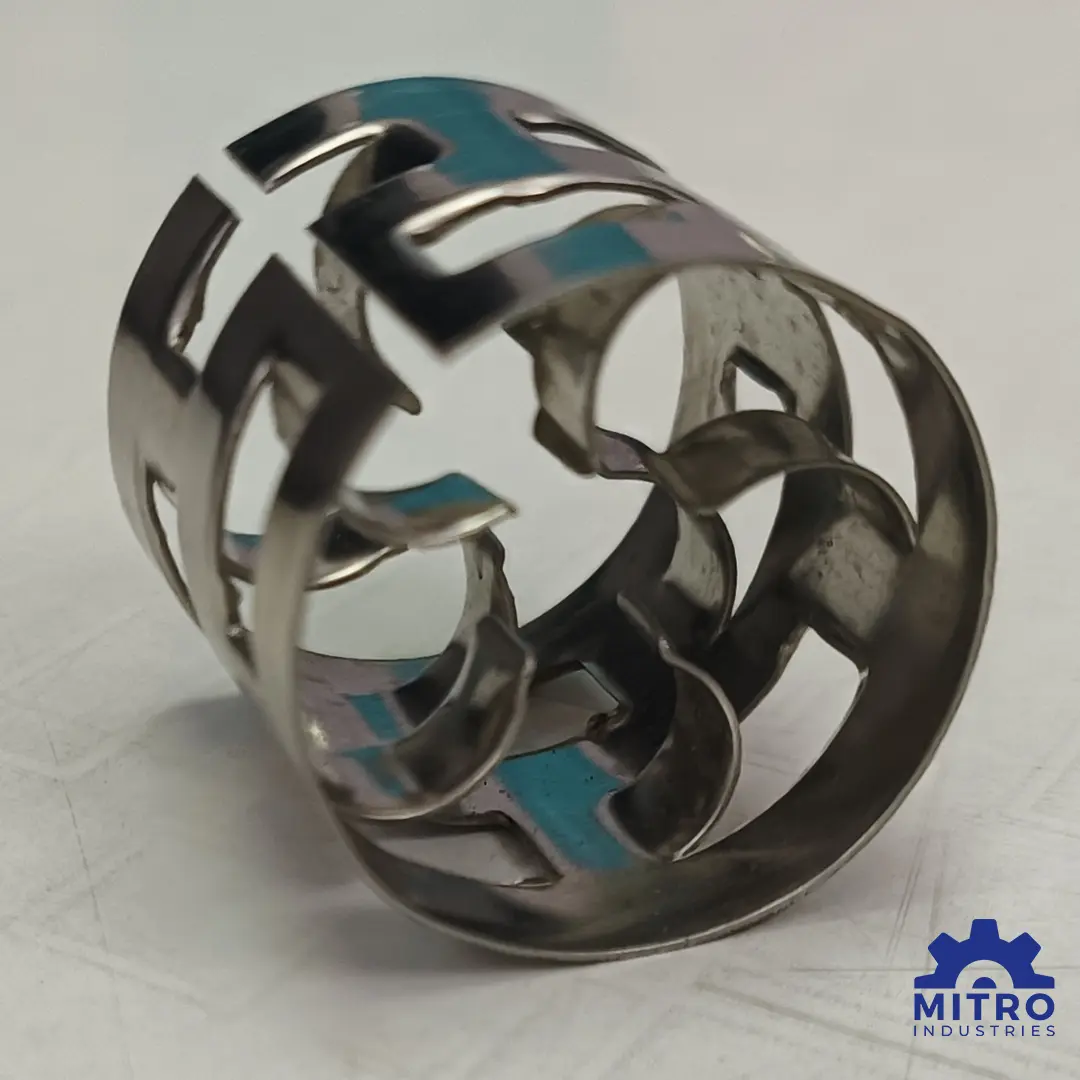

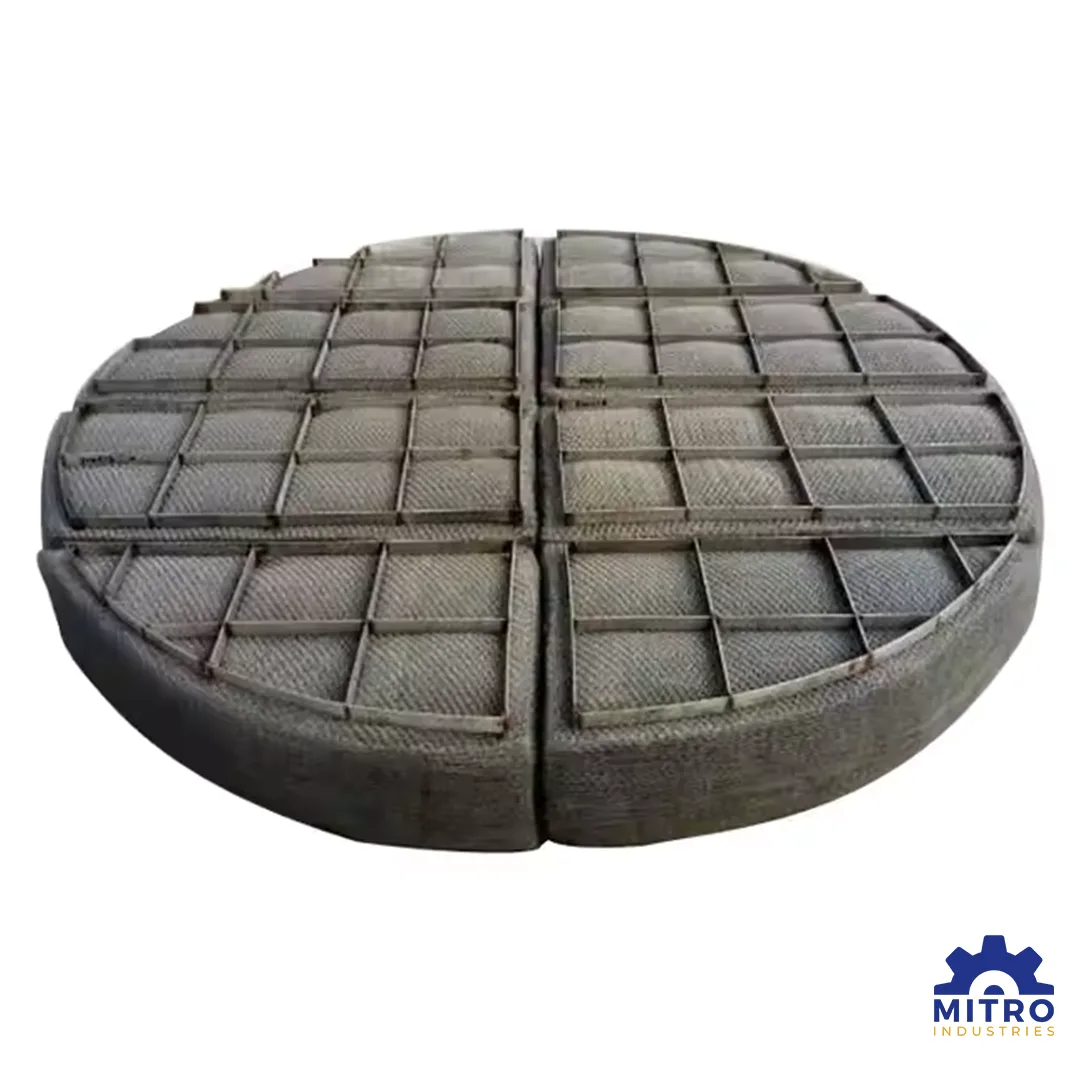

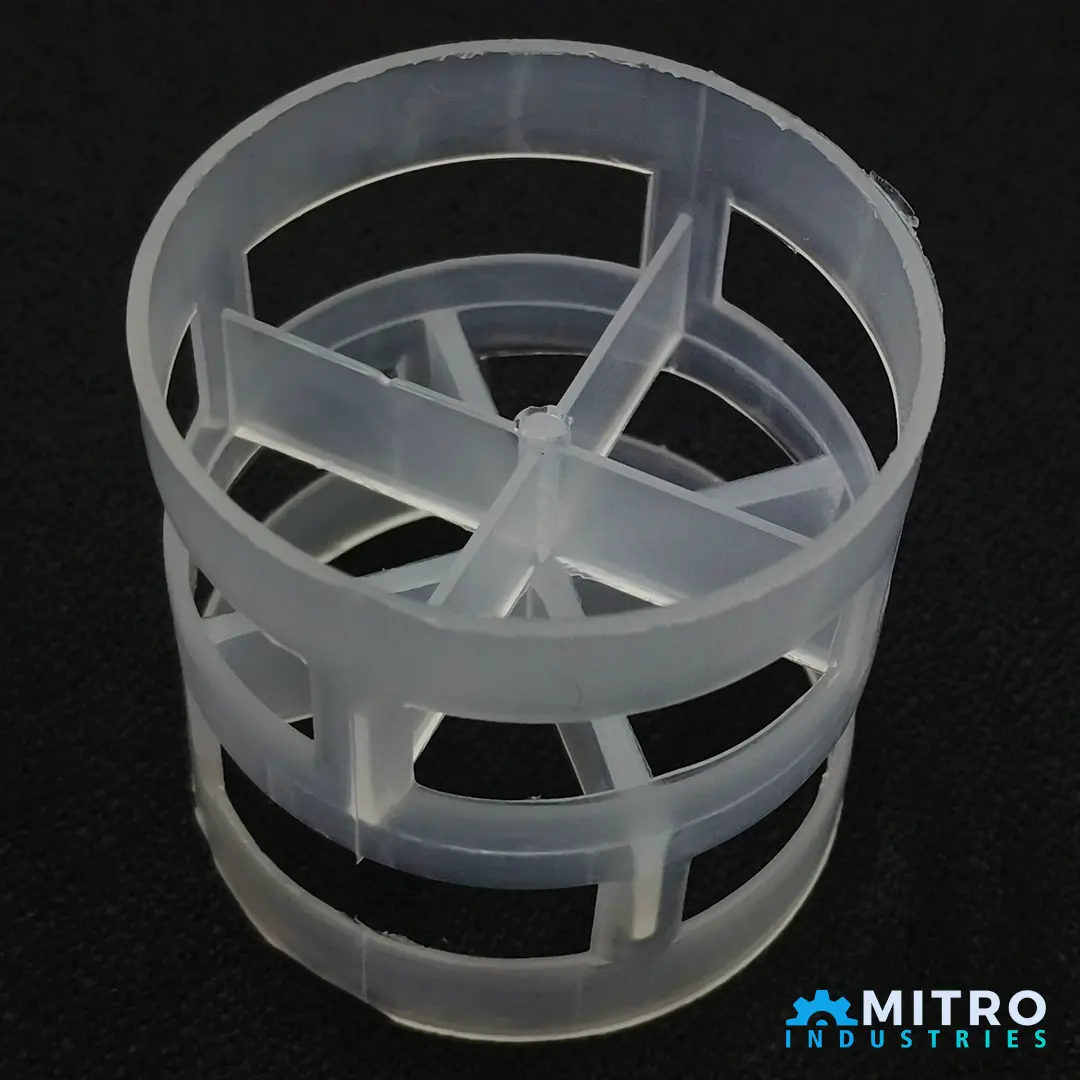

Product related to Tower Packing

Find a similar products you may like