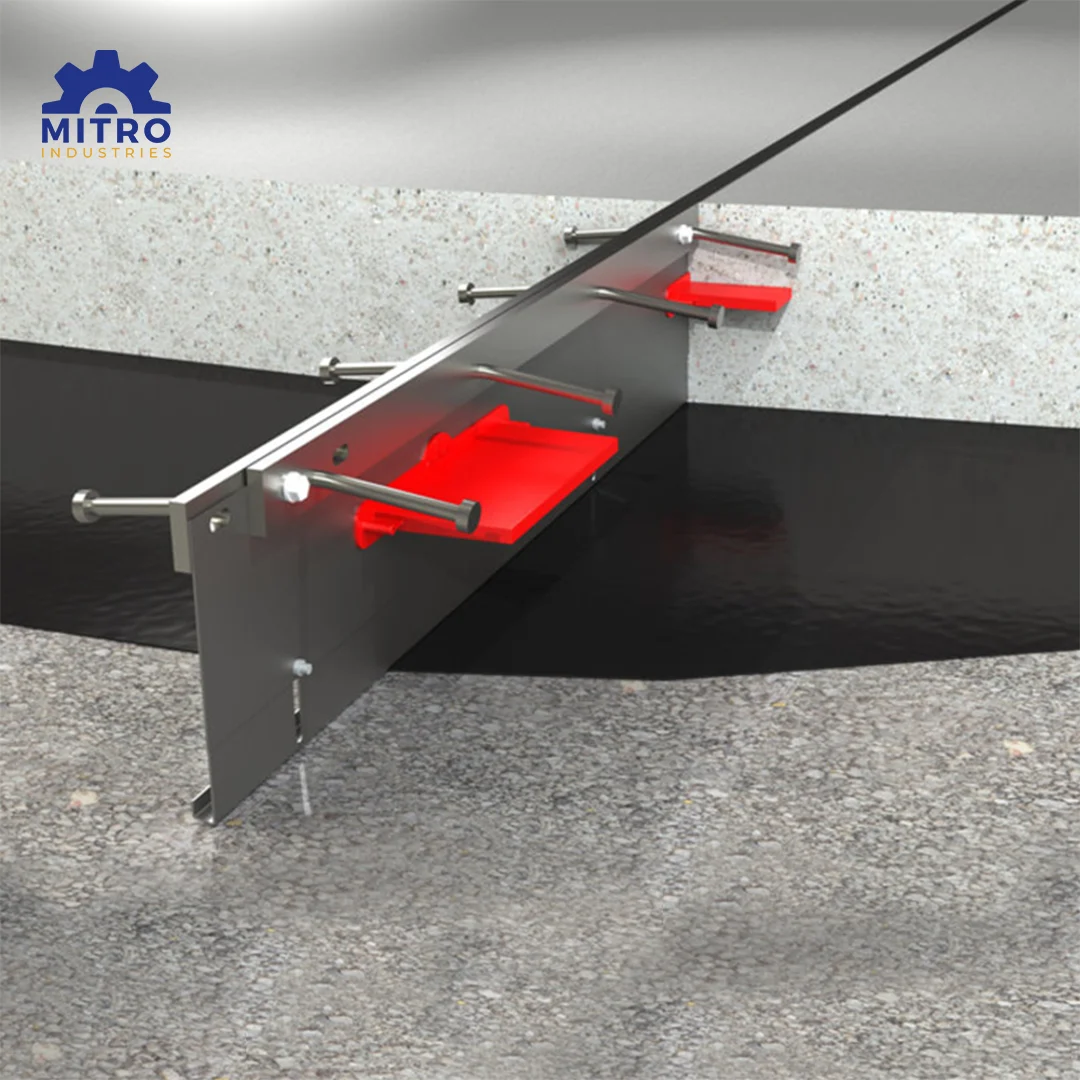

Steel Armour Joints

Armour joints are used to control cracking, accommodate movement, and enhance the structural integrity of the floor. View Complete Details...

Product Specification

Steel armour joints are an essential component in concrete flooring systems, especially in large-scale industrial or commercial buildings where durability and resistance to wear are crucial.

Purpose of Steel Armour Joints

Steel armour joints serve multiple functions in concrete flooring

1. Crack Control - Concrete naturally shrinks as it cures, and cracks can develop over time due to stress, temperature changes, or external loads. Steel armour joints help control where cracks occur by providing a predetermined point for the concrete to move without creating undesirable, unsightly cracks.

2. Movement Accommodation - Concrete floors can experience movement due to temperature fluctuations, moisture changes, and building settlement. Steel armour joints allow for this movement while preventing damage to the floor or adjacent surfaces.

3. Structural Support - These joints contribute to the floor's overall strength by distributing loads and stresses more evenly, especially in areas with heavy traffic, machinery, or other stressors. The steel component helps reinforce the joint, ensuring it remains intact and capable of withstanding mechanical wear.

4. Durability - Steel armour is highly durable, providing excellent protection against impact and abrasion in high-traffic areas. This makes it especially beneficial in environments like warehouses, factories, or parking garages where the floor experiences heavy loads or potential damage from forklifts, vehicles, and machinery.

Components of Steel Armour Joints

Steel armour joints generally consist of

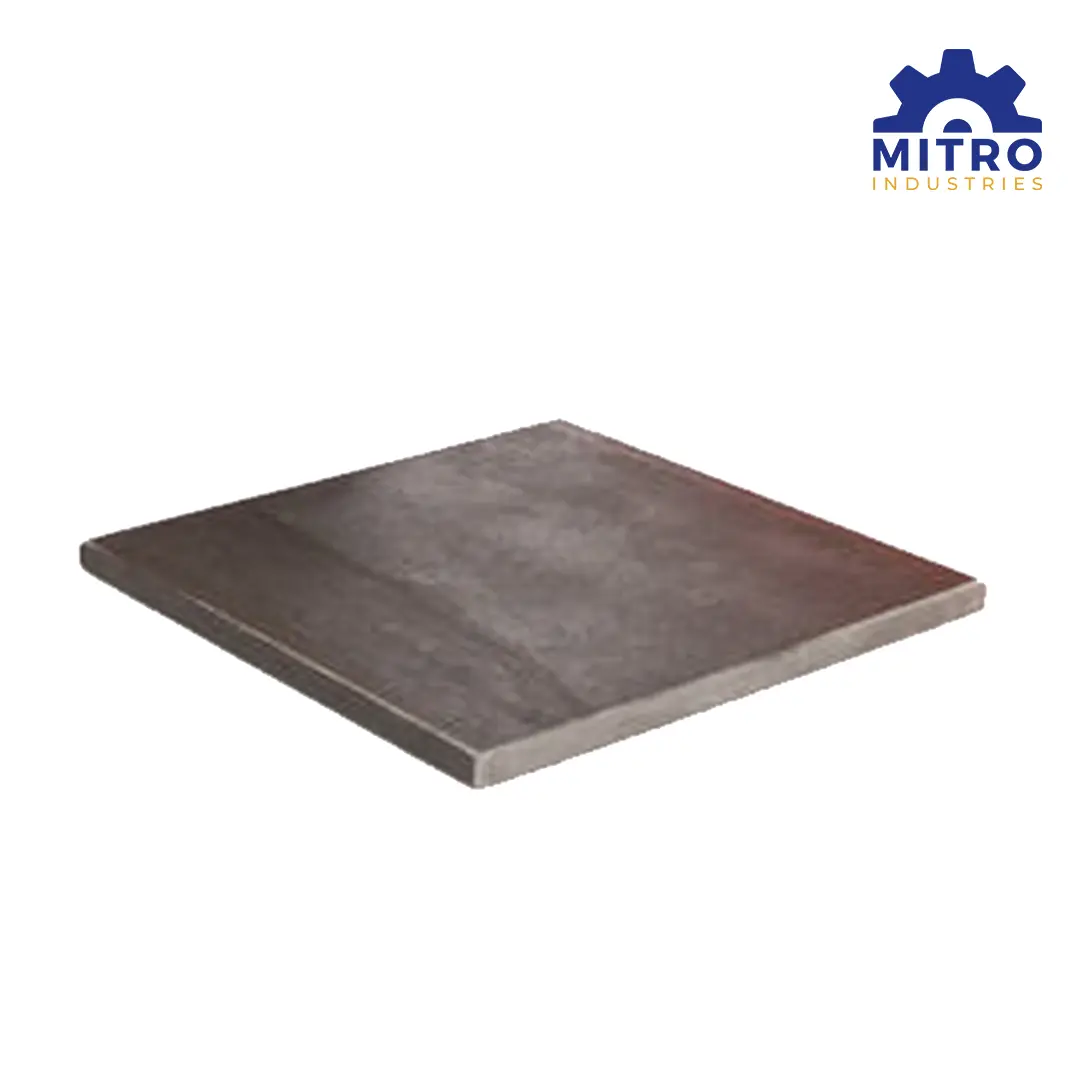

• Steel/MS plates - These components are designed to resist wear and prevent the joint from separating over time. The steel plate often sits flush with the floor surface.

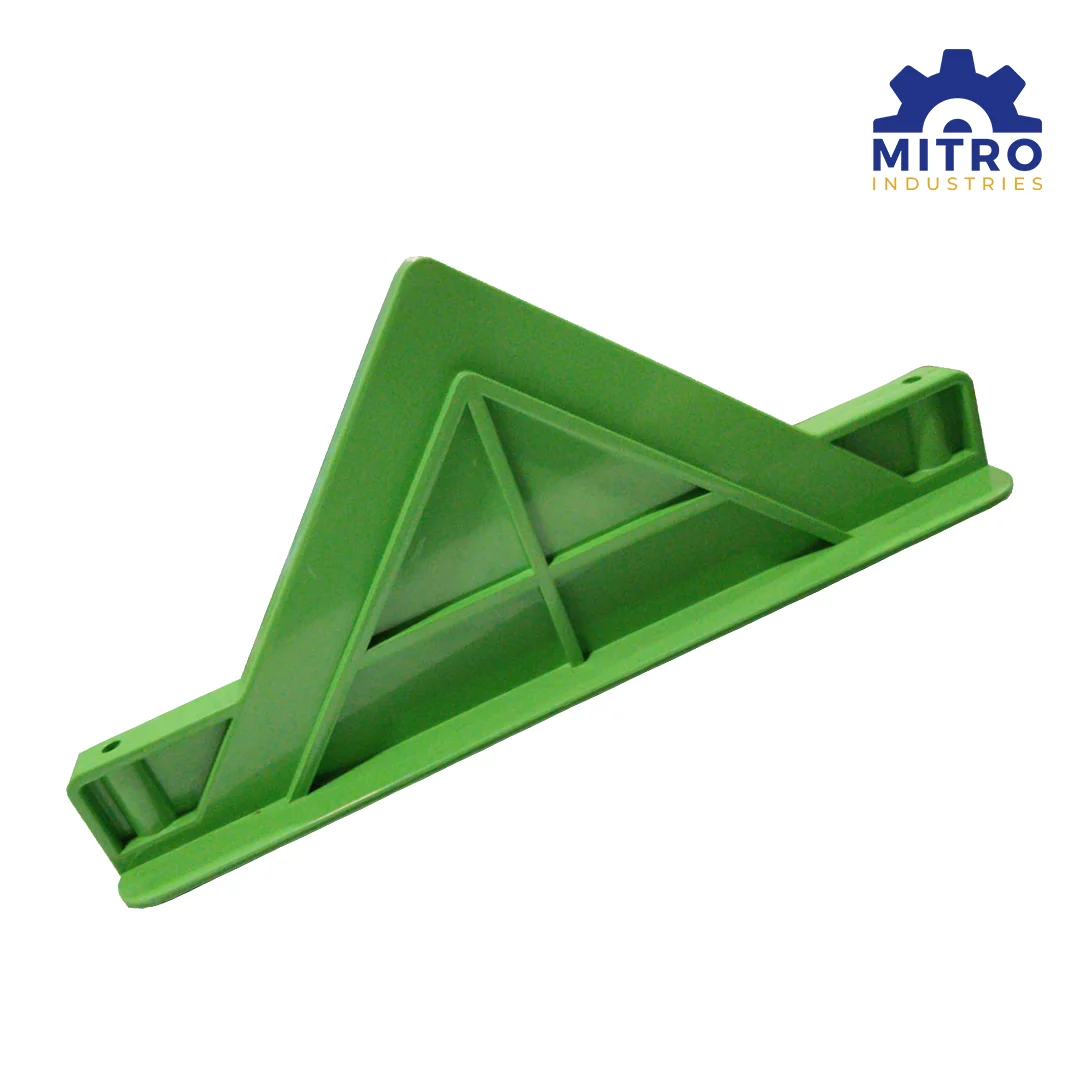

• ABS Sleeve or other sealing materials - In some cases, rubber or other flexible materials are used alongside the steel armour to seal the joint and minimize dust, moisture, or debris infiltration. This is especially important for maintaining a clean environment in industries like food processing.

• Nylon/MS/SS bolts or fixing mechanisms - The steel plates are typically secured to the concrete slab using anchor bolts or other mechanisms to ensure the joint remains secure and aligned.

Types of Steel Armour Joints

1. Expansion Joints - These joints accommodate the natural expansion and contraction of the concrete slab due to temperature changes.

2. Contraction Joints - These are designed to control cracking by creating a controlled point where the concrete is more likely to crack, minimizing random cracks.

3. Isolation Joints - Used to isolate sections of the slab, steel armour isolation joints prevent stresses from transferring across different parts of the floor.

Installation Process

The installation of steel armour joints typically involves several key steps

1. Preparation of the Floor Slab - Before installing the joint, the floor slab must be prepared by ensuring it is properly leveled and cured.

2. Placement of the Joint - Steel plates are placed in the desired location, often in the form of continuous strips along the flooring or at specific points where expansion and contraction are expected.

3. Fixing and Securing the Steel - The steel plates are then secured with anchors, ensuring they are properly embedded in the concrete and flush with the slab’s surface.

4. Sealing - In some cases, flexible sealing materials may be added to ensure the joint is fully sealed and protected from the elements.

Product related to Flooring System

Find a similar products you may like