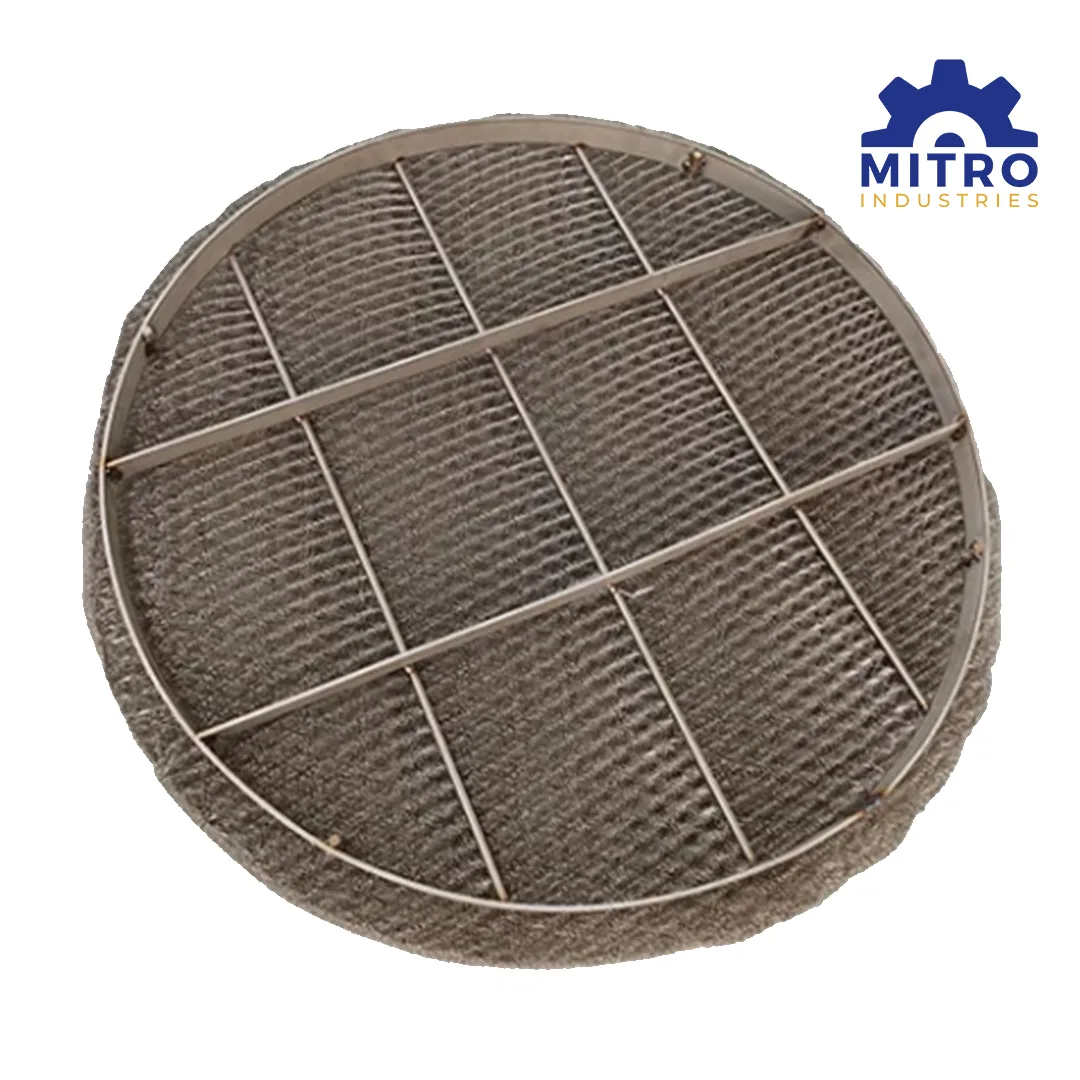

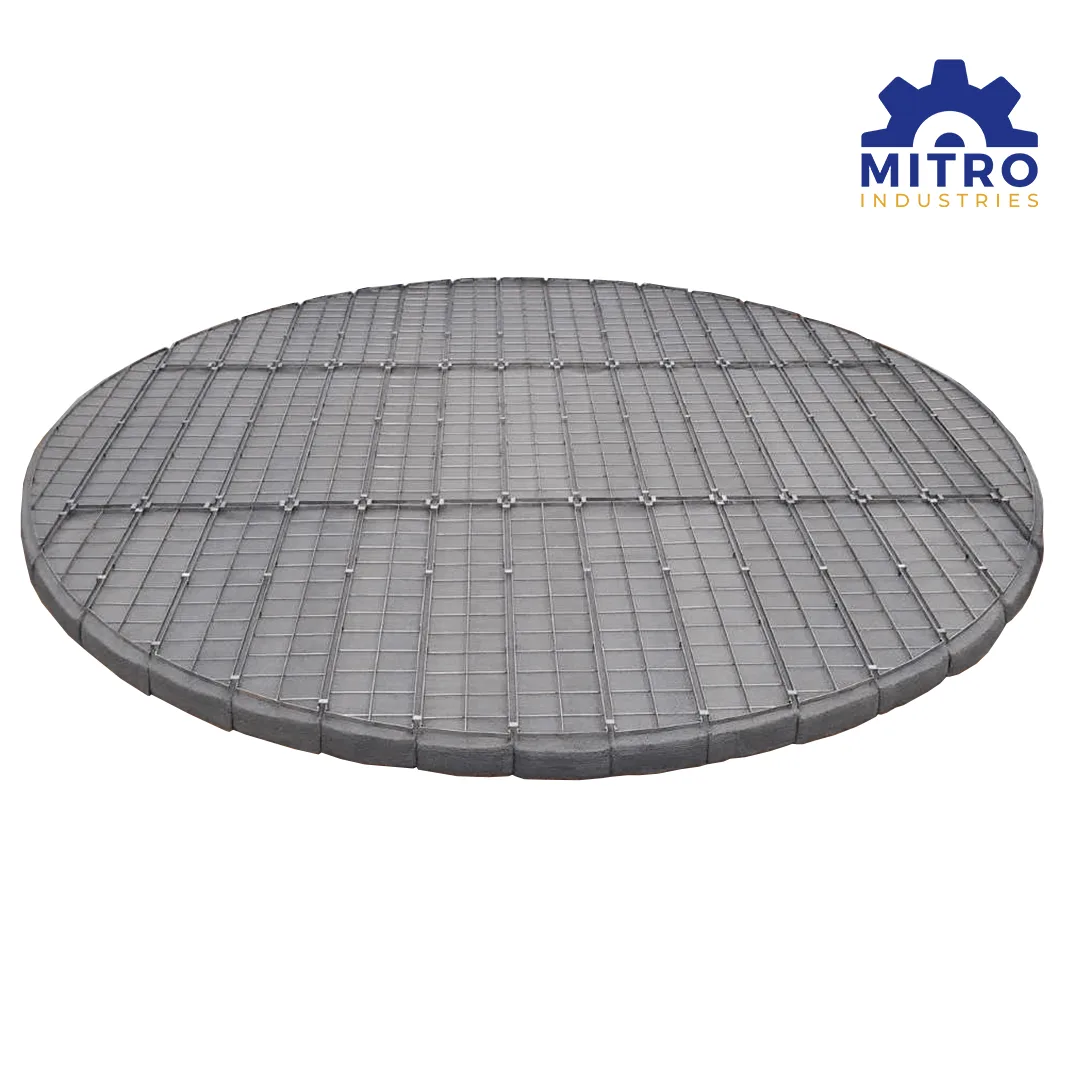

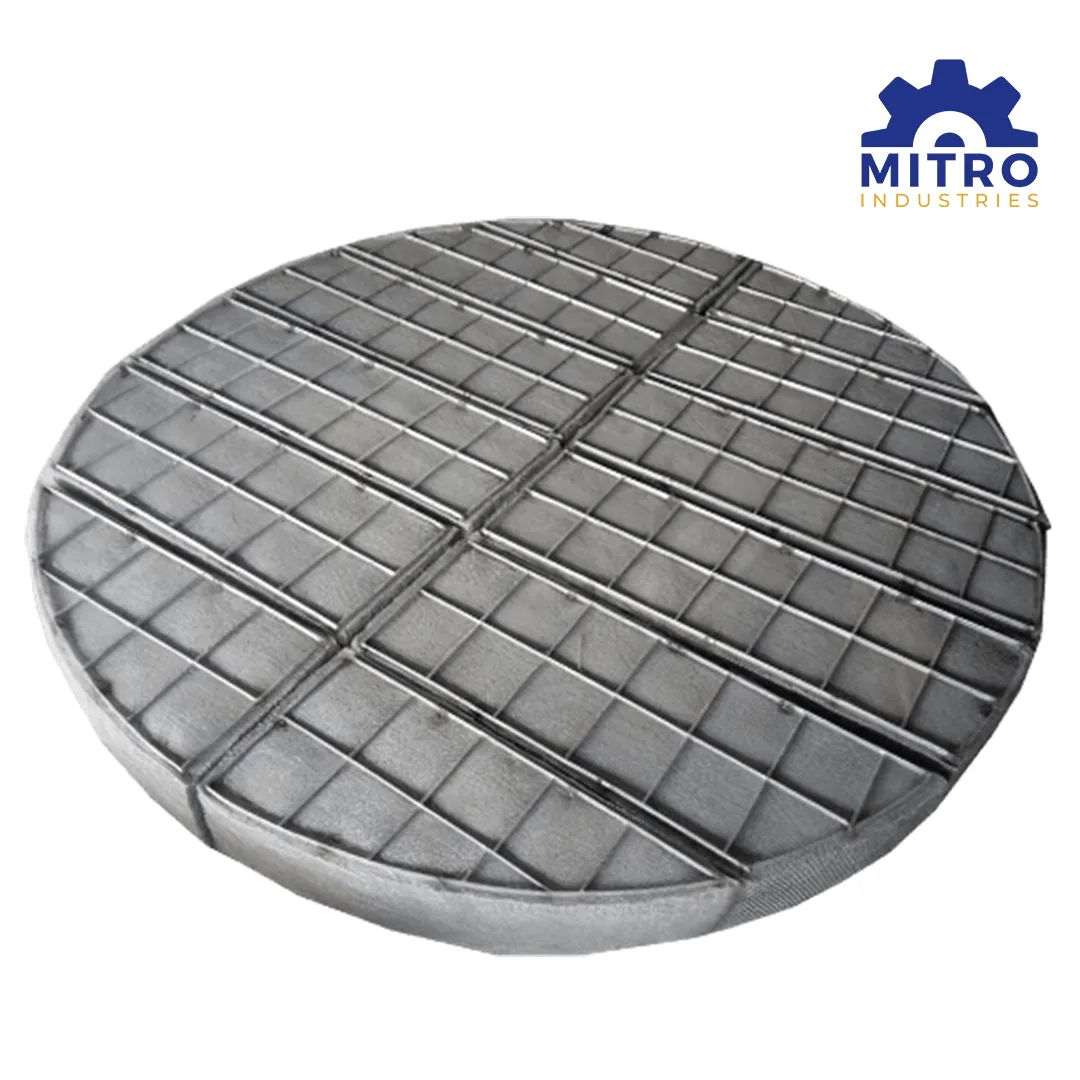

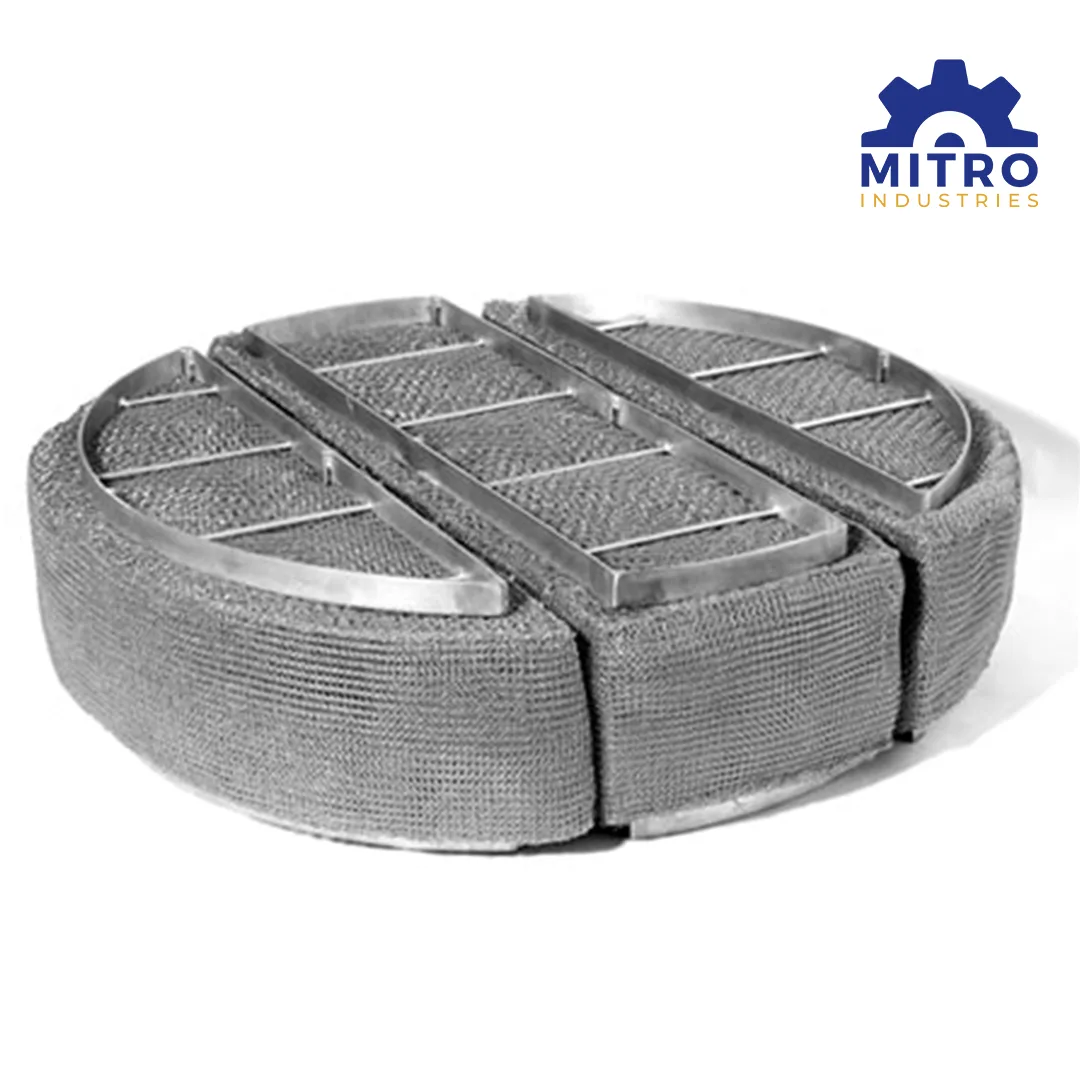

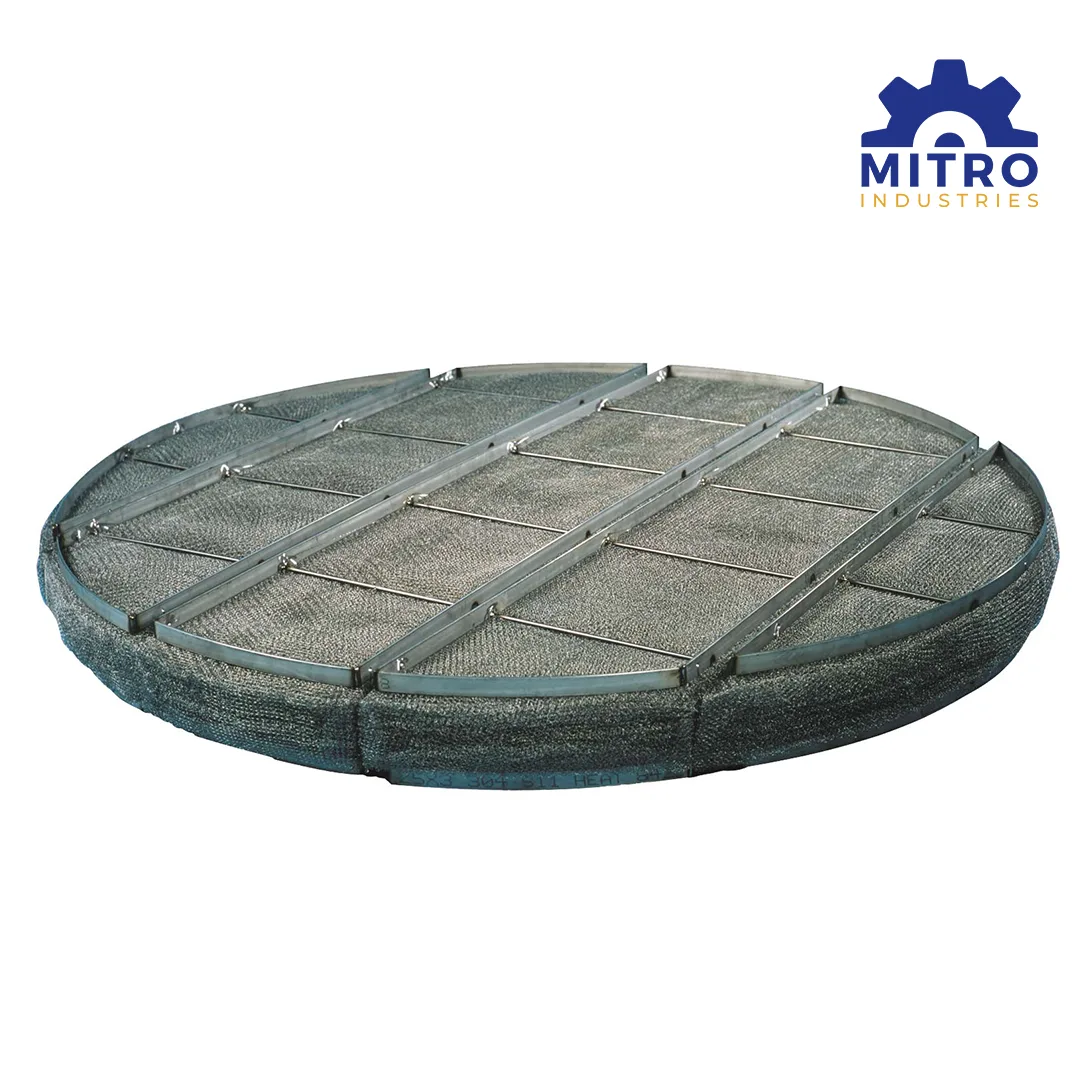

Wiremesh Demister Pad

Mitro Industries designs and manufactures high-efficiency demister pads (mist eliminators) for gas-liquid separation in chemical, petrochemical, and pharmaceutical industries. View Complete Details...

Products also required!

Product Specification

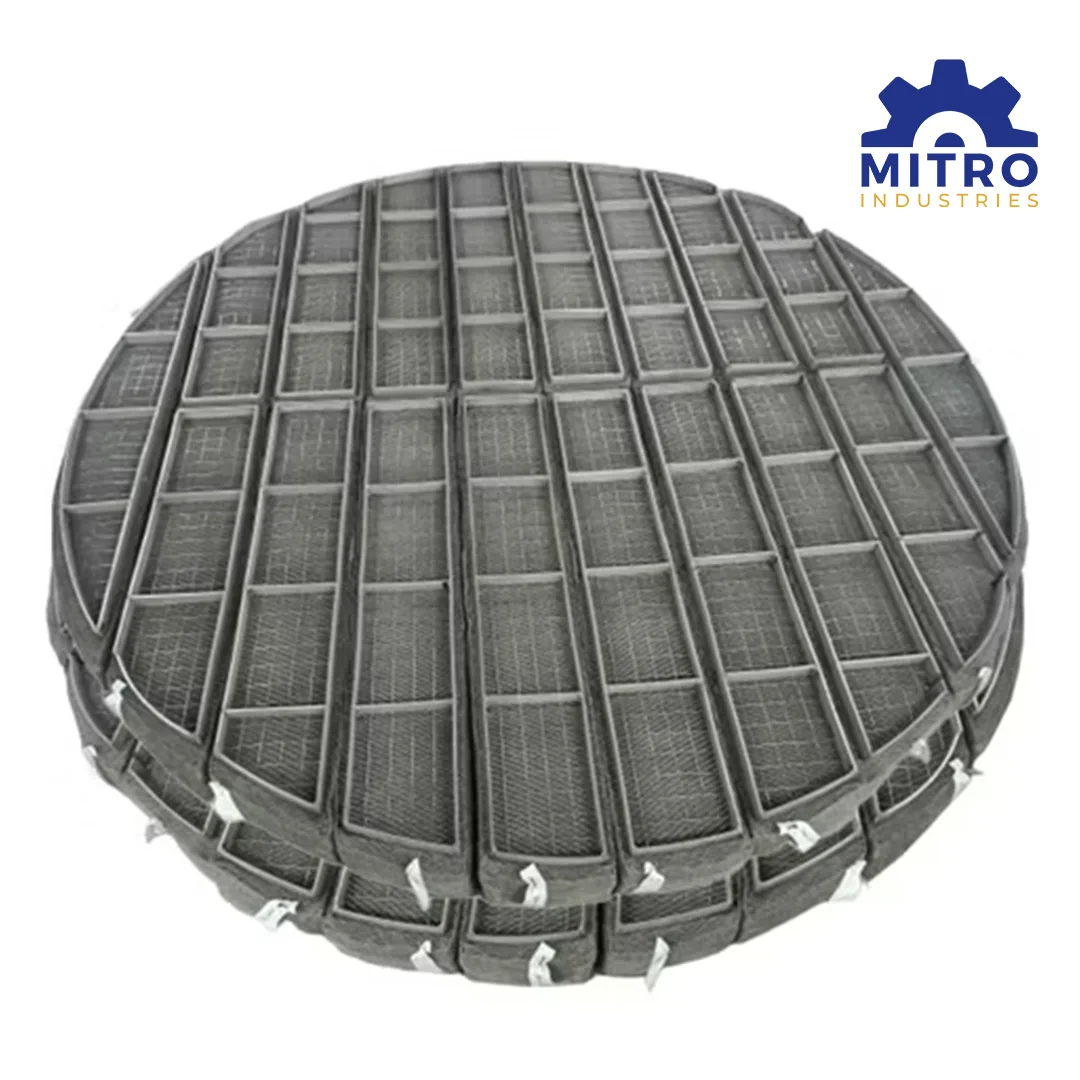

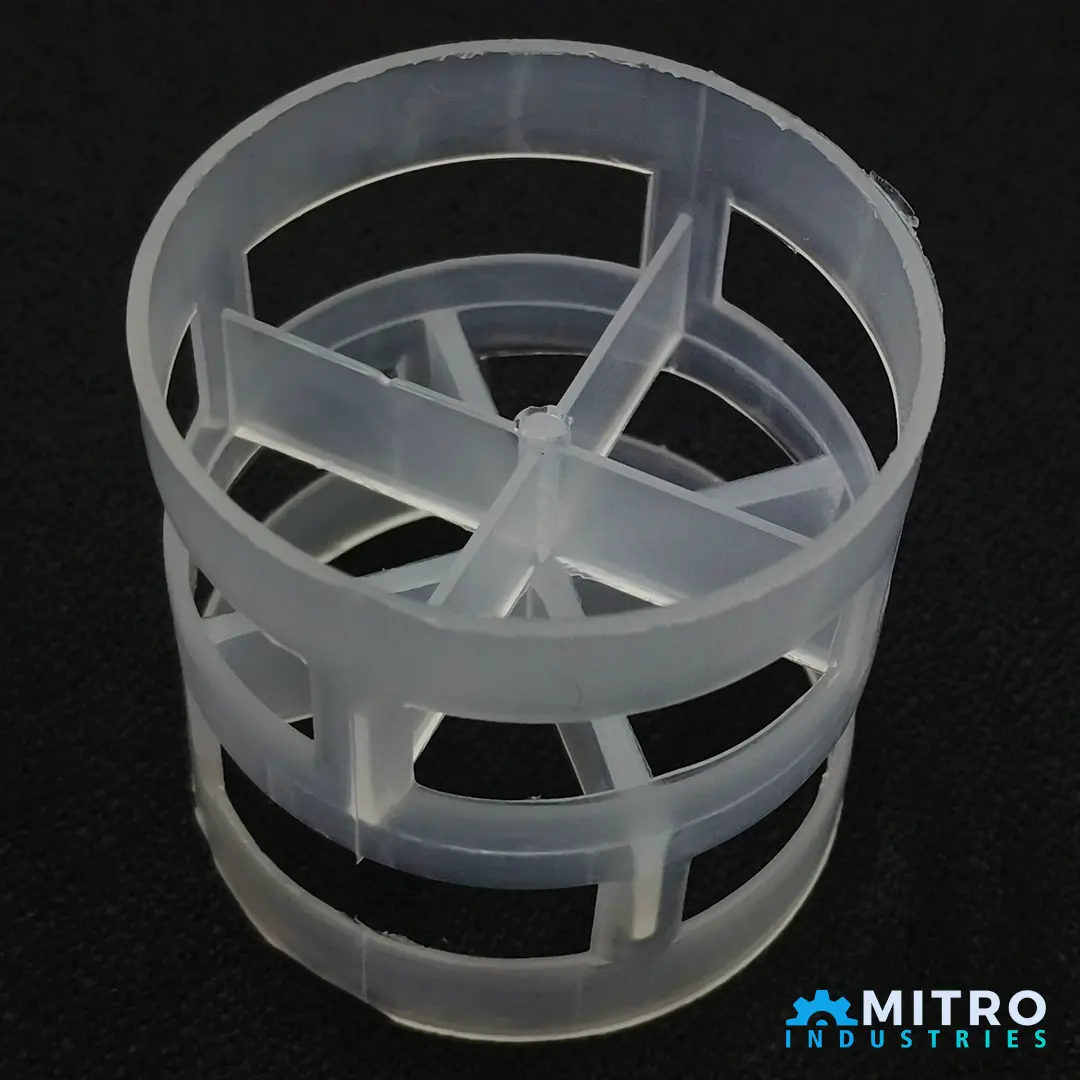

Mitro Industries specializes in the Design, Manufacture, and Supply of a comprehensive range of Demister Pads, also known as Mist Eliminators, Mesh Pads, or Wire Mesh Demisters. Our demister pads are engineered for efficient gas-liquid separation, making them ideal for use in moisture removal from compressed air, column packing, and steam separation systems.

These high-performance mist eliminators are widely applied across various sectors including the chemical, petroleum, and pharmaceutical industries, as well as in separation and filtration equipment. Mitro Demister Pads are particularly effective in separating entrained liquid droplets from vapor streams, contributing to cleaner processes and improved operational efficiency.

Typically constructed as mesh-type coalescers, our demister pads can also be designed as vane packs, depending on specific process requirements. By coalescing fine liquid droplets into larger ones that are heavy enough to settle under gravity, Mitro Demister Pads enable a compact separator vessel design. This not only optimizes equipment footprint but also enhances performance by ensuring the outgoing vapor or gas stream is free of liquid contaminants.

Working Principle

Mitro Demister Pads are designed to separate the liquid phase from the gaseous phase efficiently. As gas or vapor streams pass through the demister pad, entrained liquid droplets come into contact with the fine mesh filaments. These droplets adhere to the surface and coalesce into larger drops. When the combined droplets reach a sufficient size, they are pulled down by gravity, leaving the gas phase clean and dry. In typical setups, the cleaned gas exits from the top of the separator, while the separated liquid is drained from the bottom. This mechanism ensures high separation efficiency and process reliability.

Materials of Construction

Mitro Industries offers Demister Pads in a broad selection of materials, ensuring compatibility with diverse process environments:

• Stainless Steel : SS 304, 304L, 316, 316L, 321, 430

• High-Performance Alloys : Inconel, Monel, Nickel, Hastelloy, Alloy 20

• Non-Metallic Options : Polypropylene, Nylon, Teflon

• Other Metals : Copper

Construction & Installation Options

Mitro Demister Pads are available in

• Single-piece or Multi-piece designs for easy installation via manholes

• Configurations with or without support grids, tailored to specific customer or process requirements

Mitro Industries is committed to delivering precision-engineered demister solutions that enhance separation performance, reduce vessel size, and improve the efficiency of your process systems.

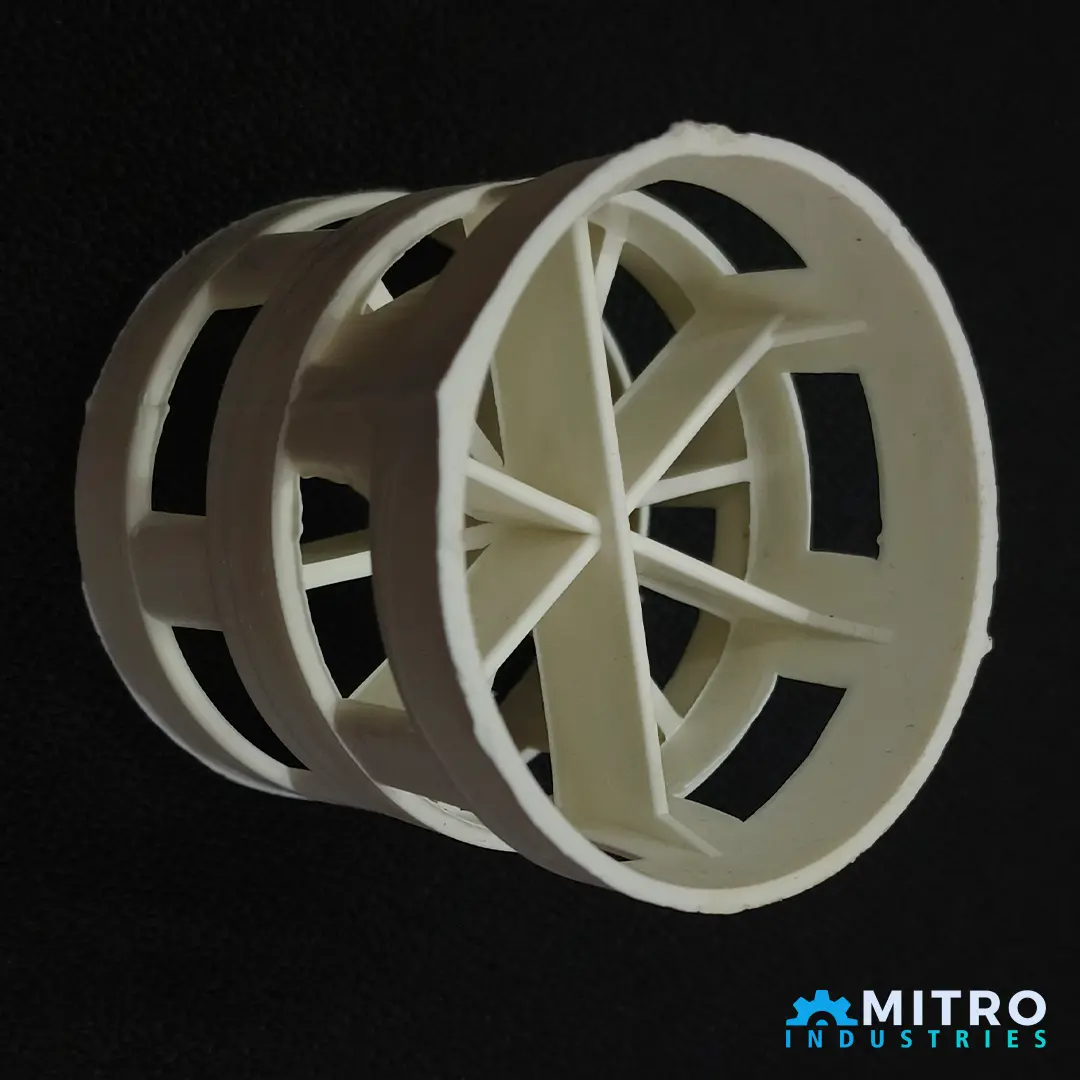

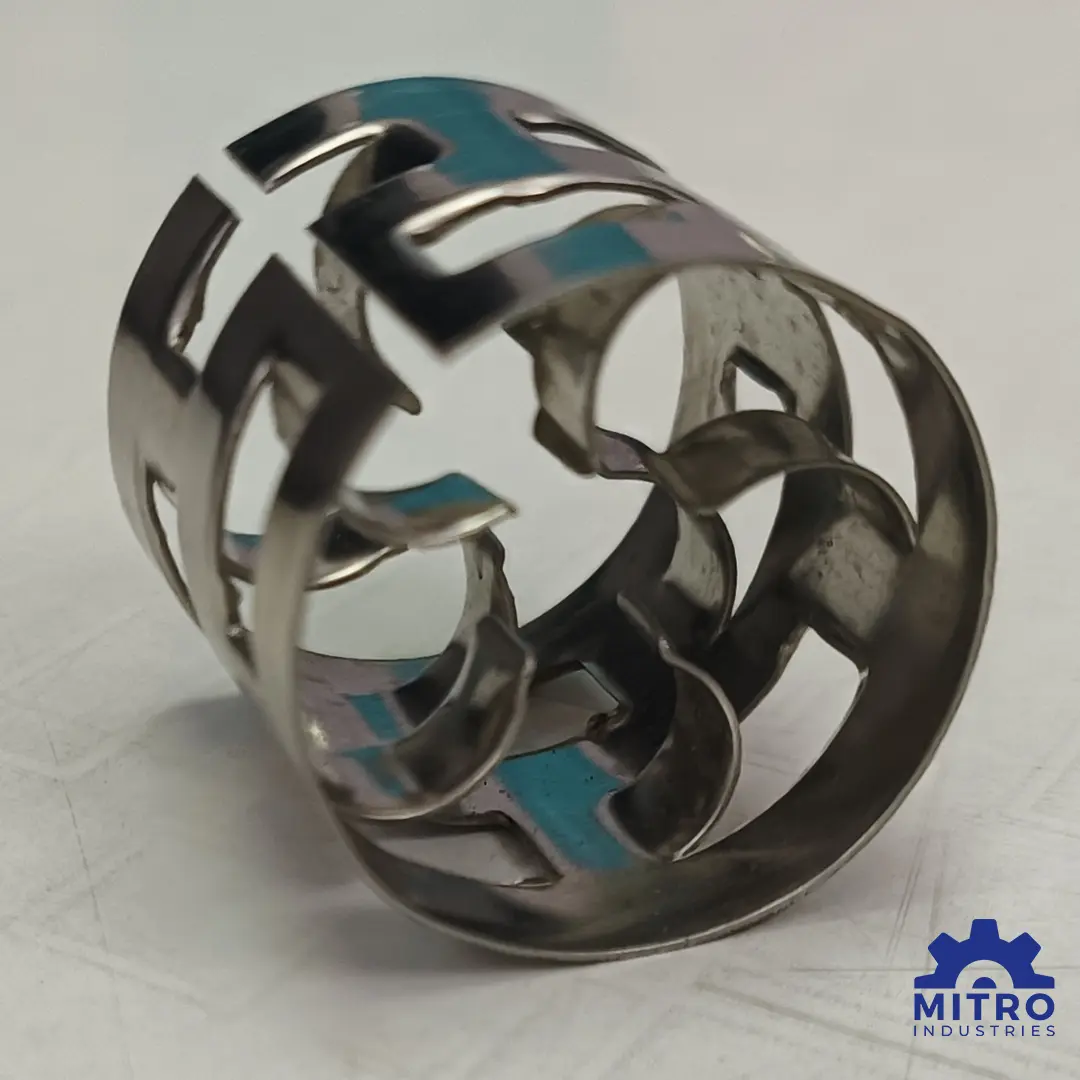

Product related to Tower Packing

Find a similar products you may like