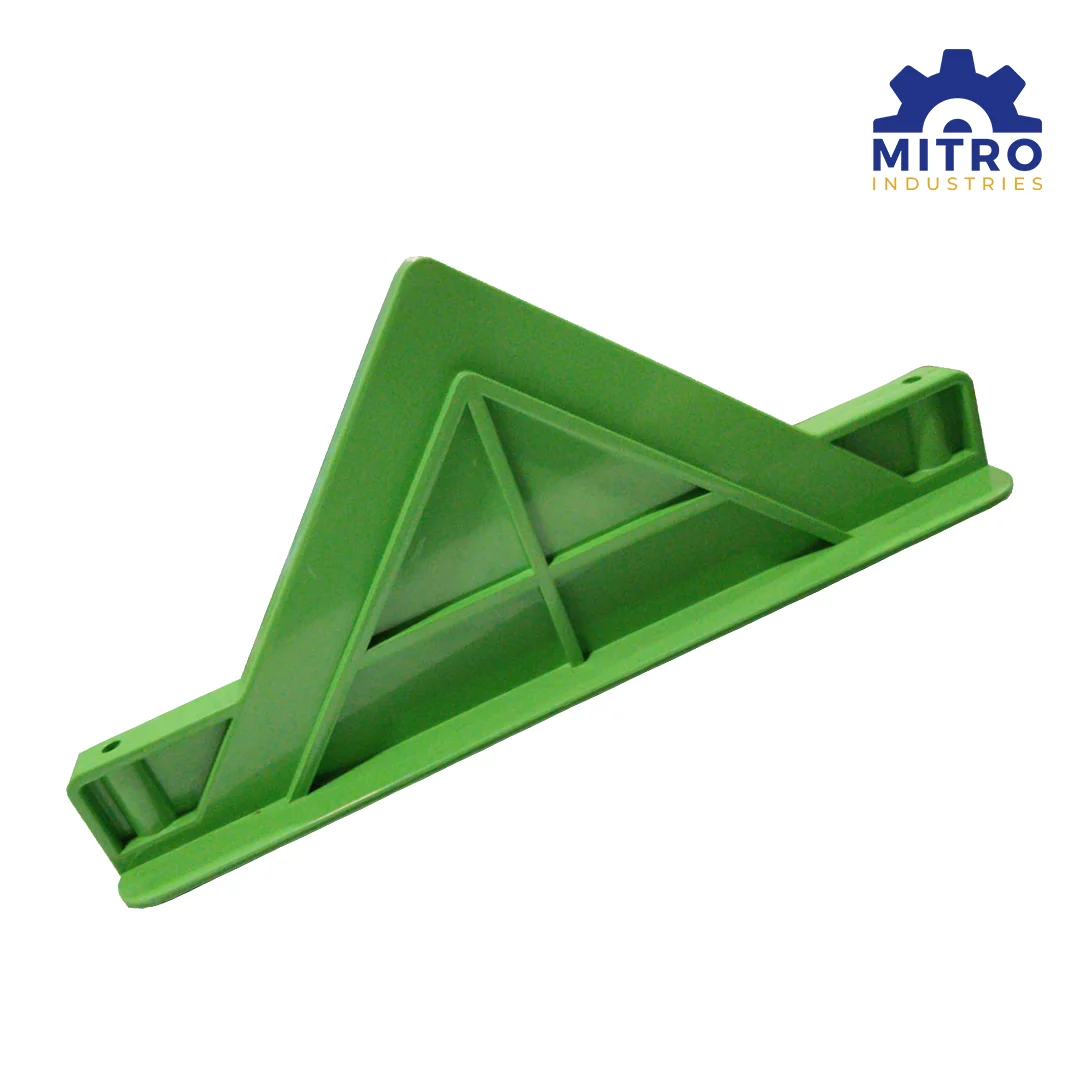

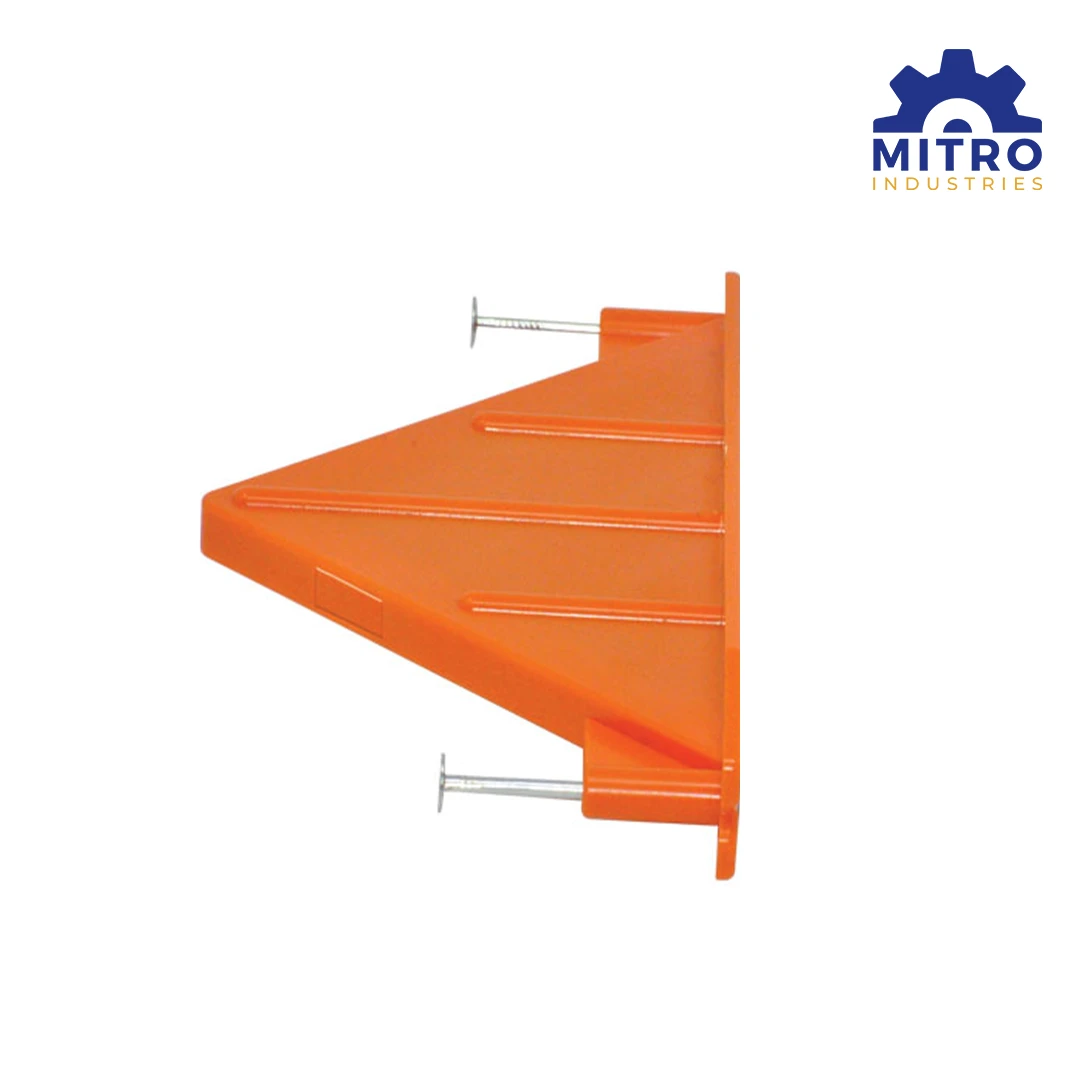

Diamond Dowel Sleeve

A diamond dowel sleeve is an essential component used in armour joints for industrial and commercial flooring systems. View Complete Details...

Product Specification

It plays a crucial role in reinforcing the joint structure by facilitating the proper alignment and movement between adjacent floor slabs. These sleeves are designed to work in conjunction with dowel bars and dowel plates to ensure the durability and stability of flooring systems subjected to heavy loads, extreme wear, and environmental factors.

What is a Diamond Dowel Sleeve?

A dowel sleeve is essentially a cylindrical sleeve made from durable materials (often steel or other high-strength alloys) that encases or surrounds the dowel bar inserted into a floor joint. The diamond dowel sleeve refers to a specific design where the sleeve has a cross-section or texture shaped like a diamond. This unique shape is not only functional for the alignment of the dowels but also enhances the strength of the joint.

The sleeve serves as a guide for the dowel bars, ensuring they remain properly aligned during the curing and settling process of the concrete or other flooring material. The diamond design improves the sleeve’s load-bearing capacity and reduces the risk of misalignment under heavy or dynamic stresses.

Purpose of Diamond Dowel Sleeves in Armour Joints

In armour joint flooring, the primary goal is to create a durable and robust connection between concrete slabs or other flooring materials. Diamond dowel sleeves contribute to this by providing

Alignment Control - The sleeve helps maintain proper alignment between adjacent floor slabs. This is crucial for preventing cracks or uneven wear due to misalignment, which can occur from heavy traffic or equipment movements.

Load Transfer Efficiency - Dowel bars inside the sleeves allow forces (from traffic, equipment, or thermal expansion) to be efficiently transferred between the slabs. The diamond shape of the sleeve helps evenly distribute these forces across the joint, minimizing stress concentrations that could lead to cracks.

Preventing Slab Movement - By holding the dowel bars securely in place and providing a smooth pathway for them to move slightly without compromising the integrity of the joint, the sleeves help control horizontal slab movement. This is important in floors that experience expansion or contraction due to temperature changes, moisture levels, or heavy loads.

Reducing Friction - The diamond-shaped internal surface of the dowel sleeve is often designed to reduce friction between the dowel bar and the sleeve. This feature allows for slight horizontal movement between the slabs without restricting necessary movement, thus enhancing the joint's overall flexibility and longevity.

Protecting Dowel Bars - The sleeves help shield the dowel bars from environmental factors such as corrosion, moisture, and chemicals, which could weaken the dowel bars over time. This protection is vital in environments like warehouses, loading docks, or factories, where floors are exposed to harsh conditions.

Key Features of Diamond Dowel Sleeves

Material Strength - Typically made from high-strength steel, stainless steel, or other corrosion-resistant alloys, the sleeves are designed to withstand significant wear and tear. The material ensures the sleeve maintains its shape and strength under extreme conditions.

Diamond Cross-Section - The distinctive diamond shape in the cross-section of the sleeve allows for better stress distribution and enhances the sleeve’s ability to handle both static and dynamic loads. It provides additional grip and stability for the dowel bars.

Corrosion Resistance - Since the sleeve will often be exposed to moisture or chemicals, corrosion-resistant coatings or materials like galvanized steel or stainless steel are often used to prolong the lifespan of the sleeve.

Ease of Installation - The sleeves are designed for easy insertion and positioning within pre-formed holes or grooves in the floor joint. Their design allows for a straightforward installation process, which reduces labor time and cost.

Customizable Dimensions - The size, diameter, and length of diamond dowel sleeves can be customized according to the specific needs of the floor, load requirements, and type of traffic the floor will bear. This ensures optimal performance for different flooring applications.

Applications

Diamond dowel sleeves are used in a wide variety of flooring systems, including

Industrial Concrete Floors - Warehouses, factories, and heavy-duty manufacturing plants where floors must support substantial weight and dynamic loads.

Parking Garages and Ramps - High-traffic areas where vehicles and heavy machinery frequently pass over.

Loading Docks - Areas subject to heavy forklift or truck traffic where floor slabs need to maintain alignment.

Airport Terminals - Large public spaces with high foot traffic and large vehicles, requiring robust and durable flooring systems.

Benefits of Diamond Dowel Sleeves

Enhanced Joint Performance - The primary benefit of using diamond dowel sleeves is the superior performance of the floor joints. These sleeves ensure the efficient transfer of loads, protect the integrity of the slabs, and maintain smooth, stable connections.

Increased Durability - By preventing misalignment and controlling slab movement, the sleeves help extend the life of the flooring system, reducing the frequency of costly repairs or replacements.

Improved Safety - A properly installed diamond dowel sleeve reduces the risk of floor joint failure, which could otherwise lead to uneven surfaces, cracks, or even dangerous tripping hazards in high-traffic areas.

Cost-Effective - While the initial cost of installing diamond dowel sleeves may be higher than traditional joint reinforcement methods, the long-term savings from fewer repairs, replacements, and reduced downtime make it a cost-effective solution.

the diamond dowel sleeve is a vital element in armour joint systems for flooring that enhances both the stability and longevity of concrete and industrial floors. By providing alignment control, load distribution, and protection to dowel bars, it ensures that joints remain strong and resistant to cracking, even under heavy or dynamic loads. Whether in industrial warehouses, commercial spaces, or high-traffic public areas, the diamond dowel sleeve ensures that floors stay intact and functional for years, making it an indispensable tool for modern flooring systems.

Product related to Flooring System

Find a similar products you may like